A high-quality metal cut off wheel is an indispensable tool for anyone working with metal, whether in professional fabrication, construction, or DIY projects. These abrasive discs, designed for use with angle grinders or chop saws, make quick work of cutting through various metallic materials like steel, rebar, aluminum, and stainless steel. Choosing the right cut off wheel can significantly impact your efficiency, safety, and the quality of your cuts, making durability, speed, and material compatibility crucial considerations. Our comprehensive guide delves into the best options available, helping you select the perfect cut off wheel for metal to tackle your toughest tasks with precision and ease.

Quick Product Comparison

Our Top 5 Metal Cut Off Wheel Reviews – Expert Tested & Recommended

1. 4-1/2 Inch Diamond Cut Off Wheels for Metal, Angle Grinder, 7/8″ Arbor, 3 Pack

These 4-1/2 inch diamond cut off wheels from FOXBC are engineered to deliver unparalleled longevity and cutting performance. Designed for angle grinders with a 7/8″ arbor, this 3-pack provides a robust solution for a wide range of metal cutting tasks. The diamond-rimmed design ensures a significantly extended lifespan compared to traditional bonded abrasive discs, making it a cost-effective and efficient choice for demanding projects.

Key Features That Stand Out

- ✓ Up to 100X longer cutting life than standard bonded discs.

- ✓ Diamond-rimmed for enhanced durability and consistent performance.

- ✓ Ideal for dry cutting various metals: rebar, angle iron, cast iron, stainless steel, aluminum, pipes, and sheet metal.

- ✓ Advanced Electro-Plating Process ensures even distribution of diamond abrasive for precision.

- ✓ Suitable for daily heavy-duty use, offering outstanding reliability.

Why We Recommend It

We highly recommend this diamond cut off wheel pack for its exceptional durability and versatility. The diamond technology drastically reduces the frequency of wheel changes, saving time and money, especially on large projects. Its ability to handle diverse metal types with clean, precise cuts makes it a standout performer for professionals seeking efficiency and longevity.

Best For

This product is best for professionals and serious DIYers who frequently cut through a variety of metals, including rebar, steel, and cast iron, and prioritize long-lasting performance and precision.

Pros and Cons

Pros:

- Significantly extended lifespan (up to 100x conventional wheels).

- Versatile for cutting a wide range of metal types.

- Provides clean, burr-free cuts with minimal sparking.

- Consistent cutting performance due to electro-plating process.

Cons:

- Higher initial cost compared to standard abrasive wheels.

- Not ideal for applications requiring extreme flexibility.

Customer Reviews

Customer Review: I’ve used plenty of cut-off wheels over the years, but this FOXBC diamond cutting wheel is next-level. It slices through metal like butter—steel, rebar, bolts, you name it—with clean edges and minimal sparking. No wobble, no warping, just smooth, consistent performance. What really stands out is durability; I feel like I can get so much more done without constantly swapping discs.

Customer Review: Awesome blade! Well worth the money. Long lasting, hardly gets dull. Cuts through almost anything. Easily 50 cuts with no problem, still going strong. Highly recommend for serious work.

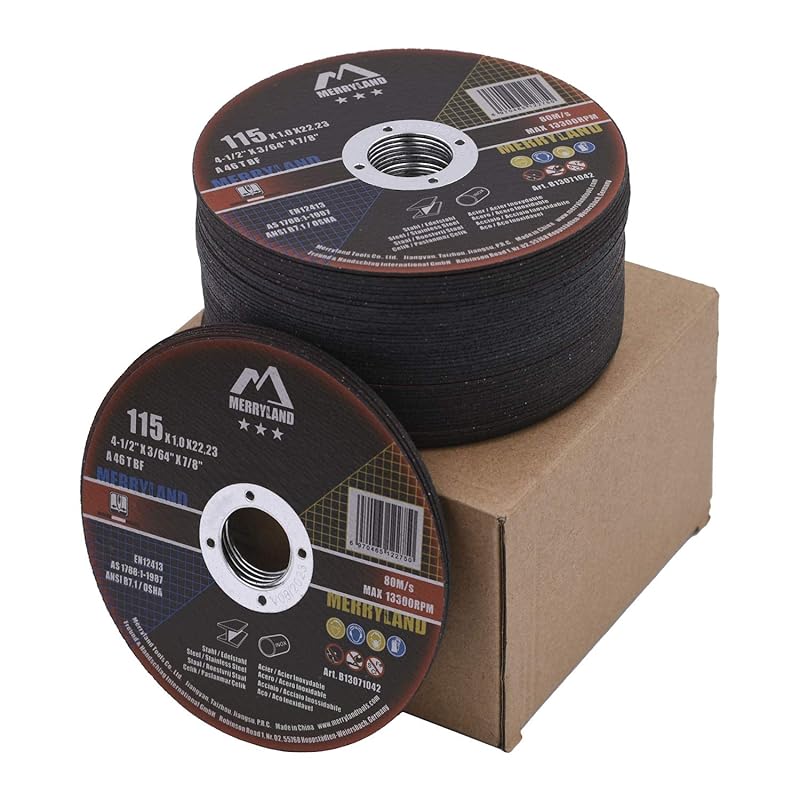

2. Metal Cut Off Wheels 4 1/2 Inch Thin for Angle Grinders, Iron and Stainless Steel.

These Merryland metal cut off wheels are designed for precision and durability when used with angle grinders. At 4-1/2 inches with a thin 0.045″ profile, they are optimized for fast, clean cuts through various metals, including iron and stainless steel. The construction utilizes German Phenolic Resin and a reinforced structure, ensuring both long life and enhanced safety during operation.

Key Features That Stand Out

- ✓ Thin 0.045″ profile for fast, smooth, and burr-free cutting.

- ✓ Made with high-quality German Phenolic Resin for enhanced lifespan.

- ✓ Reinforced with 2 layers of fiberglass mesh for safety and stability.

- ✓ Versatile application for cutting metal, iron, stainless steel (INOX), sheet metal, and various pipes.

- ✓ Professional-grade cutting disc suitable for a wide range of materials.

Why We Recommend It

We’ve chosen these as Editor’s Choice because of their excellent balance of cutting speed, longevity, and safety features. The thin design ensures minimal material loss and heat buildup, providing clean cuts, while the robust construction offers peace of mind. It’s a reliable option for both everyday tasks and more demanding projects involving diverse metal types.

Best For

Ideal for metal fabricators, welders, and serious hobbyists who require thin, precise, and safe cuts on stainless steel, iron, and other common metals using an angle grinder.

Pros and Cons

Pros:

- Achieves very clean and smooth cuts due to thin profile.

- Reinforced structure significantly enhances safety.

- Good lifespan for an abrasive disc, thanks to German resin.

- Effective on a wide variety of ferrous and non-ferrous metals.

Cons:

- Thin design requires careful handling to prevent breakage if misused.

- May wear faster than diamond-tipped wheels on extremely hard materials.

Customer Reviews

Customer Review: These Merryland cut off wheels are fantastic for stainless steel. I get really clean cuts without much effort, and they last longer than some of the other brands I’ve tried. The thinness really makes a difference for precision work.

Customer Review: Great cutting discs! I appreciate the reinforced design, it makes me feel safer when I’m grinding away. They slice through thick iron like butter and hold up well to abuse. Definitely keeping these in my workshop.

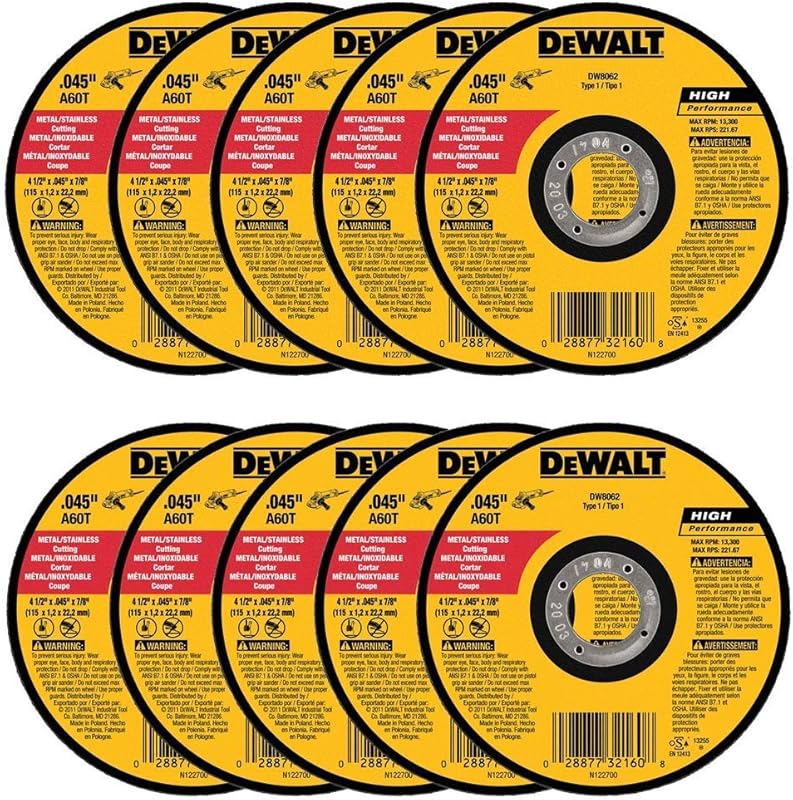

3. DeWalt DW8062 4-1/2-Inch x 0.045-Inch x 7/8-Inch Metal Cutting Wheel

The DeWalt DW8062 metal cut off wheel offers reliable performance for a budget-friendly price. This 4-1/2-inch disc features a thin 0.045-inch design and a 7/8-inch arbor, making it compatible with most angle grinders. Its proprietary aluminum oxide grain combination is engineered for aggressive cutting action, ensuring fast, burr-free cuts on various metals, characteristic of DeWalt’s quality and durability.

Key Features That Stand Out

- ✓ Thin 0.045-inch wheel design facilitates fast and burr-free cutting.

- ✓ Proprietary aluminum oxide grain ensures aggressive and efficient material removal.

- ✓ Durable construction designed for extended use.

- ✓ Standard 4-1/2-inch size with 7/8-inch arbor fits most angle grinders.

- ✓ Delivers consistent performance for various cutting applications.

Why We Recommend It

For those seeking a dependable metal cutting disc without breaking the bank, the DeWalt DW8062 is an excellent choice. It provides impressive cutting speed and clean finishes, typical of higher-priced alternatives, but at a more accessible cost. Its reliability and aggressive cutting action make it a great value for general metalwork.

Best For

This cut off wheel is best for DIY enthusiasts, light-duty contractors, and anyone needing a reliable, affordable disc for general cutting of steel, rebar, and other ferrous metals.

Pros and Cons

Pros:

- Excellent value for its performance and durability.

- Fast and clean cuts with minimal effort.

- Reliable and consistent performance.

- Widely available and compatible with most angle grinders.

Cons:

- May wear faster than premium diamond wheels on very tough materials.

- Can generate more heat and sparks compared to diamond alternatives.

Customer Reviews

Customer Review: For the price, these DeWalt wheels are hard to beat. I use them constantly for cutting rebar and steel tubing, and they hold up surprisingly well. Cuts quickly and cleanly, which is exactly what I need for my projects.

Customer Review: I’ve always trusted DeWalt, and these cut off wheels don’t disappoint. They perform just as good as more expensive brands for everyday cutting tasks. Definitely my go-to for budget-friendly quality.

4. 4 1/2 Inch Cut Off Wheels for Angle Grinders, Metal and Stainless Steel Cutting

This pack of 4 1/2 inch cut off wheels is tailored for intensive use with angle grinders, excelling at cutting through both metal and stainless steel. Featuring a thin 0.045″ cutting wheel design, these discs ensure rapid, burr-free cuts, significantly enhancing productivity. The proprietary aluminum oxide grain combination guarantees aggressive cutting action and consistent performance, making them a solid choice for demanding applications.

Key Features That Stand Out

- ✓ Optimized 4-1/2″ x 0.045″ x 7/8″ dimensions for efficient cutting.

- ✓ Thin design for fast, clean, and burr-free cuts on metal and stainless steel.

- ✓ Utilizes a proprietary aluminum oxide grain for aggressive and consistent cutting action.

- ✓ Designed for robust performance and durability in demanding conditions.

- ✓ Offers excellent compatibility with standard angle grinders.

Why We Recommend It

We recommend these abrasive cut off wheels for their impressive speed and clean cutting ability across different metal types, especially stainless steel. The combination of a thin profile and aggressive grain ensures that tasks are completed quickly and precisely. They offer a strong balance of performance and value for general fabrication and heavy-duty repairs.

Best For

Perfect for fabricators, welders, and maintenance professionals who frequently work with steel and stainless steel and require a high volume of quick, precise cuts.

Pros and Cons

Pros:

- Superior cutting speed through various metals.

- Delivers consistently clean, burr-free edges.

- Durable and maintains integrity even with heavy use.

- Excellent value, especially when purchased in bulk packs.

Cons:

- Can generate significant heat during prolonged cuts.

- May dull faster on exceptionally hard or thick alloys.

Customer Reviews

Customer Review: I have used Dewalt, Diablo (the worst), Avanti, and other brands and I can say with confidence these are superior. Their composition is better, more durable, don’t flex as much, and cut faster IF YOU LET THE TOOL DO ITS JOB. That was for the geniuses who burn up tools and tool bits because they’re impatient.

Customer Review: The best discs I’ve ever used, and they wear evenly. I cut 20 old rusted bolts with brackets and I’m still on the first disc. They just keep going, very impressed with the longevity and cut quality.

5. Diamond Metal Cut Off Wheel 4 1/2 x 7/8 Inch for Rebar, Steel, and Iron

The EZARC diamond metal cut off wheel is a revolutionary cutting solution, promising an exceptionally long lifespan and superior performance. Measuring 4-1/2 x 7/8 inches, this wheel employs advanced diamond technology, allowing it to deliver significantly more cuts than conventional bonded discs. It’s engineered for dry cutting a comprehensive range of metals, including rebar, steel, iron, alloy steel, and aluminum, making it a true all-in-one metal cutting solution.

Key Features That Stand Out

- ✓ Advanced diamond technology delivers 5,000+ cuts, equating to 100x the life of bonded wheels.

- ✓ Versatile “All in 1 Metal Solution” for rebar, steel, iron, alloy steel, aluminum, pipes, and sheet metal.

- ✓ Solid steel wheel body greatly reduces the risk of shatter and injury for enhanced safety.

- ✓ Designed for dry cutting, eliminating the need for coolant.

- ✓ Offers a significantly lower cost per cut over its lifespan.

Why We Recommend It

This diamond cut off wheel stands out for its incredible durability and cost-effectiveness over time. The substantial increase in cuts per wheel, combined with enhanced safety features, makes it a highly efficient and economical choice for frequent metal cutting. It’s a game-changer for anyone looking to maximize productivity and minimize downtime.

Best For

This is the ultimate choice for heavy-duty commercial users, structural fabricators, and contractors who need to cut a variety of tough metals regularly and prioritize safety and long-term value.

Pros and Cons

Pros:

- Extremely long lifespan reduces replacement costs and downtime.

- Highly versatile across a broad spectrum of metal materials.

- Enhanced safety due to solid steel body construction.

- Consistent, efficient cutting performance.

Cons:

- Higher initial investment compared to traditional abrasive wheels.

- May not be as aggressively fast on certain materials as a fresh bonded disc.

Customer Reviews

Customer Review: Just received it 10 min ago, and came right on time when I needed it. Of course, I have another ones, but I wanted to try this one. I had doubts it would cut through that metal, but… unfortunately, I’m speechless. If I say something negative that will be the biggest lie I ever said. No regrets by purchasing this, it’s amazing.

Customer Review: These EZARC Cutting wheels eat through metal like a knife through hot butter!! I thoroughly recommend!!! I use them to cut through HVAC housing. I go through a disk about every 2 months; it goes through the old school HVAC thickest housings as well. These disks and my 3 1/2” cut off saw have made my job so much easier.

Complete Buying Guide for Metal Cut Off Wheel

Essential Factors We Consider

When selecting the ideal metal cut off wheel, several critical factors must be taken into account to ensure optimal performance, safety, and value. First, consider the material you’ll be cutting; different wheels are optimized for specific metals like stainless steel, cast iron, or aluminum. The wheel diameter and arbor size must match your cutting tool, typically an angle grinder or chop saw. Common diameters include 4-1/2 inch, 7 inch, and 14 inch. The thickness of the wheel is also crucial: thinner wheels (e.g., 0.045 inch) provide faster, cleaner, and more precise cuts with less material loss, while thicker wheels offer greater durability for heavy-duty applications but might be slower. The abrasive grain type (e.g., aluminum oxide, zirconia alumina, or diamond) dictates the wheel’s aggression and lifespan. Aluminum oxide is standard for general metal, while zirconia alumina offers more durability. Diamond cut off wheels provide unparalleled longevity and cutting power. Finally, always check the maximum RPM rating of the wheel to ensure it is compatible with your tool’s speed, preventing dangerous failures.

Budget Planning

Budgeting for metal cut off wheels involves more than just the upfront purchase price. While a multi-pack of conventional abrasive discs might seem cheaper initially, a single diamond cut off wheel, though more expensive, can outlast hundreds of traditional wheels. Consider the “cost per cut” by factoring in the number of cuts you expect to make over the wheel’s lifespan, combined with the time saved from fewer wheel changes. For occasional light-duty tasks, a standard aluminum oxide wheel offers good value. However, for continuous, heavy-duty metal fabrication or professional use, investing in durable zirconia alumina or especially diamond wheels will lead to significant long-term savings and increased productivity. Don’t compromise on safety for cost; always choose reputable brands that meet industry safety standards.

Final Thoughts

Choosing the right metal cut off wheel is a strategic decision that impacts both your project’s outcome and your workshop’s efficiency. By carefully evaluating the material to be cut, the wheel’s specifications (diameter, thickness, arbor), the abrasive type, and safety ratings, you can make an informed choice. Prioritize a balance between cutting speed, durability, and cost to find a wheel that not only performs excellently but also aligns with your budget and usage frequency. Investing in high-quality cutting discs for metal will ultimately lead to cleaner cuts, safer operations, and greater satisfaction with your metalworking endeavors.

Frequently Asked Questions

Q: What is the difference between an abrasive cut off wheel and a diamond cut off wheel for metal?

A: Abrasive cut off wheels are made from materials like aluminum oxide or zirconia alumina, bonded together. They cut by grinding away material, and they gradually wear down and shrink in diameter during use. Diamond cut off wheels, on the other hand, have industrial diamonds bonded to their edge. They cut by fracturing and abrading the material, not by wearing down the wheel itself significantly. This gives them a significantly longer lifespan (up to 100 times or more) and consistent cutting depth, but they usually have a higher initial cost.

Q: Can I use a metal cut off wheel on wood or other non-metal materials?

A: No, metal cut off wheels are specifically designed for cutting metal. Using them on wood, plastic, or other materials can be extremely dangerous. The wheel can grab, shatter, or cause kickback, leading to serious injury. Always use the correct blade or disc designed for the material you are working with.

Q: What safety precautions should I take when using a metal cut off wheel?

A: Safety is paramount when using cut off wheels. Always wear appropriate Personal Protective Equipment (PPE) including safety glasses or a face shield, heavy-duty gloves, ear protection, and a dust mask. Ensure your angle grinder or chop saw has its guard properly installed and adjusted. Never use a damaged or cracked wheel, and always operate the tool at its rated RPM, ensuring it doesn’t exceed the wheel’s maximum RPM. Secure your workpiece firmly to prevent movement during cutting.

Q: How do I know what size cut off wheel I need?

A: The size of the cut off wheel (diameter and arbor hole) must match the specifications of your cutting tool (angle grinder, chop saw). Common angle grinder sizes are 4-1/2 inch, 5 inch, 6 inch, and 7 inch, typically with a 7/8 inch arbor. Chop saws usually use larger wheels, such as 12 inch or 14 inch, often with a 1 inch arbor. Always check your tool’s manual for recommended wheel sizes.

Q: Why are some metal cut off wheels thicker than others?

A: The thickness of a metal cut off wheel affects its performance. Thinner wheels (e.g., 0.045 inch) are designed for faster cutting, less material waste, and cleaner, more precise cuts, making them ideal for sheet metal or stainless steel. Thicker wheels offer greater rigidity and durability, making them more suitable for heavy-duty applications, deeper cuts, or when stability is prioritized over speed, though they might remove more material and generate more heat.

Selecting the right metal cut off wheel is essential for efficiency, precision, and safety in any metalworking task. Whether you’re a professional fabricator or a dedicated DIYer, our top picks offer a range of options to suit various needs and budgets, from long-lasting diamond wheels to high-performance abrasive discs. By considering the factors in our buying guide and adhering to safety protocols, you can confidently choose the best cut off wheel for metal that will deliver exceptional results project after project. Don’t let your next metal cutting job be a struggle – invest in quality and experience the difference!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.