Looking to dive into the world of welding? We’ll be exploring the basics of MIG welding, giving beginners like yourself a solid understanding of this popular welding technique. MIG welding, also known as Gas Metal Arc Welding (GMAW), is a process that uses a consumable wire electrode and a shielding gas to join two pieces of metal together.

Whether you’re a DIY enthusiast or an aspiring welder, this comprehensive guide will walk you through everything you need to know about MIG welding. We’ll cover the equipment and materials required, safety precautions, setting up your welder, choosing the right welding technique, troubleshooting common issues, and much more.

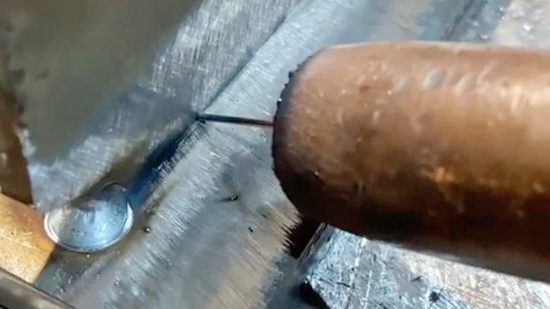

Photo by myhistorypark

With its versatility, speed, and ease of use, MIG welding is a great introductory technique for beginners. So let’s get started on your journey to mastering the art of MIG welding!

What is Mig Welding?

MIG welding is a welding technique that utilizes a consumable wire electrode and a shielding gas to create an electric arc between the electrode and the workpiece. This arc generates intense heat, which melts the wire electrode and the base metal, resulting in a strong and durable weld. MIG welding is widely used in industries such as automotive, construction, and manufacturing due to its versatility and efficiency.

One of the key advantages of MIG welding is its ability to join a wide range of metals, including carbon steel, stainless steel, and aluminum. This makes it a popular choice for various applications, from repairing metal structures to fabricating metal components. Additionally, MIG welding offers excellent control over the welding process, allowing welders to produce clean and precise welds.

Advantages of Mig Welding

MIG welding offers several advantages that make it a preferred choice for both beginners and professionals. One of the main advantages is its versatility. MIG welding can be used to weld various metals of different thicknesses, making it suitable for a wide range of applications. Whether you’re working with thin sheet metal or thick structural steel, MIG welding can handle it all.

Another advantage of MIG welding is its speed. Compared to other welding processes, such as stick welding or TIG welding, MIG welding is much faster. The continuous wire feed allows for a continuous welding process, reducing the time spent on starting and stopping. This makes MIG welding an efficient choice for large-scale projects where time is of the essence.

MIG welding is relatively easy to learn and master, especially for beginners. The process itself is straightforward, and with some practice, you can achieve consistent and high-quality welds. The availability of automatic and semi-automatic MIG welding machines further simplifies the process, making it accessible to welders of all skill levels.

Mig Welding Equipment and Safety Precautions

Before diving into MIG welding, it’s essential to familiarize yourself with the equipment and safety precautions involved. Here are the key components you’ll need for MIG welding:

MIG Welding Machine

A MIG welding machine consists of a power source, wire feeder, and a welding gun. There are various types of MIG welding machines available, including transformer-based, inverter-based, and multi-process machines. Choose a machine that suits your welding needs and budget.

Wire Electrode

The wire electrode is the consumable wire that is fed through the welding gun during the welding process. It comes in various diameters and materials, such as carbon steel, stainless steel, and aluminum. Select the appropriate wire electrode based on the type of metal you’re welding.

Shielding Gas

The shielding gas is essential in MIG welding as it protects the weld pool from contaminants and oxidation. The most common shielding gases used in MIG welding are argon and carbon dioxide. The type of shielding gas you choose depends on the material you’re welding and the desired weld characteristics.

Welding Helmet

A welding helmet is a crucial safety gear that protects your eyes and face from harmful UV radiation, sparks, and debris. Choose a helmet with an auto-darkening lens for better visibility and convenience.

Welding Gloves and Clothing

Welding gloves and clothing made of flame-resistant materials are necessary to protect your hands and body from heat, sparks, and potential burns. Ensure that your clothing covers your entire body and avoid wearing synthetic materials that can melt.

Ventilation and Fire Safety

MIG welding produces fumes and gases that can be harmful if inhaled. Ensure that you work in a well-ventilated area or use an exhaust system to remove the fumes. Additionally, have a fire extinguisher nearby to address any potential fire hazards.

Mig Welding Techniques and Settings

To achieve successful MIG welds, understanding the proper techniques and settings is essential. Here are some key considerations when it comes to MIG welding techniques and settings:

Joint Preparation

Before welding, ensure that the joint surfaces are clean, free from rust, paint, and other contaminants. Proper joint preparation ensures optimal weld penetration and strength.

Travel Speed

Maintaining a consistent travel speed is important in MIG welding. Too slow of a travel speed can result in excessive heat buildup and possible burn-through, while too fast of a travel speed may lead to insufficient fusion. Practice controlling your travel speed to achieve a smooth and even weld bead.

Welding Position

MIG welding can be done in various positions, including flat, horizontal, vertical, and overhead. Each position requires different techniques and adjustments to achieve proper weld quality. Practice welding in different positions to become comfortable and proficient in each.

Voltage and Wire Feed Speed

Adjusting the voltage and wire feed speed settings on your welding machine is crucial for achieving the desired weld characteristics. Higher voltage and wire feed speed settings are generally used for thicker materials, while lower settings are suitable for thinner materials. Experiment with different settings to find the optimal combination for your specific welding project.

Welding Technique

MIG welding offers several techniques, including stringer beads, weave beads, and tack welds. Each technique has its own advantages and is suitable for different applications. Practice and experiment with different techniques to find the one that works best for your specific project.

Choosing the Right Mig Welding Wire and Gas

Selecting the appropriate welding wire and gas is crucial for achieving high-quality welds in MIG welding. Here are some factors to consider when choosing the right MIG welding wire and gas:

Material Compatibility

Ensure that the welding wire is compatible with the base metal you’re working with. Different materials require different types of welding wire, such as ER70S-6 for carbon steel, ER308L for stainless steel, and ER4043 for aluminum.

Wire Diameter

The wire diameter determines the thickness of the weld bead and the amount of heat input. Choose a wire diameter that matches the thickness of the material you’re welding. Thicker wires are suitable for welding thicker materials, while thinner wires are used for thinner materials.

Gas Selection

The choice of shielding gas depends on the material being welded and the desired weld characteristics. Pure argon is commonly used for welding non-ferrous metals like aluminum, while a combination of argon and carbon dioxide is used for carbon steel. Consult the welding wire and gas manufacturer’s recommendations for the best gas selection.

Gas Flow Rate

Proper gas flow rate is crucial for effective shielding and weld quality. Adjust the flow rate according to the manufacturer’s recommendations, ensuring that the gas coverage is sufficient to protect the weld pool from contaminants.

Gas Purity

Ensure that the shielding gas you use is of high purity to avoid introducing impurities into the weld. Impurities can affect the weld quality and result in defects.

Consult with your local welding supplier or refer to the welding wire and gas manufacturer’s recommendations for specific guidance on choosing the right welding wire and gas for your projects.

Common Mig Welding Mistakes and How to Avoid Them

MIG welding, like any other welding process, has its share of common mistakes that beginners often make. Here are some common MIG welding mistakes and how to avoid them:

Poor Weld Preparation

Inadequate joint preparation can lead to weak and incomplete welds. Before welding, ensure that the joint surfaces are clean, free from contaminants, and properly aligned. Beveling the edges of thicker materials can improve weld penetration.

Improper Wire Stickout

Wire stickout refers to the length of the wire electrode protruding from the welding gun. Improper wire stickout can lead to inconsistent arc stability and erratic welds. Follow the manufacturer’s recommendations for the correct wire stickout length.

Incorrect Voltage and Wire Feed Speed

Incorrect voltage and wire feed speed settings can result in poor weld quality. Refer to the welding machine’s user manual and adjust the settings according to the material thickness and desired weld characteristics.

Inconsistent Travel Speed

Inconsistent travel speed can result in uneven weld beads and inadequate fusion. Maintain a steady and consistent travel speed throughout the welding process.

Insufficient Shielding Gas Coverage

Inadequate shielding gas coverage can lead to weld contamination and porosity. Ensure that the gas flow rate is set correctly and that the nozzle is positioned close to the weld joint for proper coverage.

Lack of Practice

Like any skill, MIG welding requires practice to become proficient. Take the time to practice on scrap metal or test pieces before working on actual projects. Experiment with different techniques, settings, and materials to improve your welding skills.

By being aware of these common mistakes and taking the necessary precautions, you can avoid them and produce high-quality welds.

Mig Welding Troubleshooting Tips

Even with proper technique and preparation, issues can arise during MIG welding. Here are some troubleshooting tips to help you address common welding problems:

Excessive Spatter

Excessive spatter, the molten metal that splatters during welding, can be minimized by adjusting the wire stickout, reducing the voltage, or using anti-spatter sprays or gels.

Porosity

Porosity, the presence of small holes or cavities in the weld, can be caused by excessive moisture in the shielding gas or inadequate gas coverage. Ensure that the gas supply is clean and dry, and check for proper gas flow rate and nozzle positioning.

Incomplete Fusion

Incomplete fusion occurs when the weld bead does not fully penetrate the base metal. Increase the voltage or wire feed speed to achieve better fusion, or adjust the welding technique to ensure proper heat input.

Burn-Through

Burn-through happens when excessive heat causes the base metal to melt through. Reduce the voltage or wire feed speed, or increase the travel speed to avoid burn-through.

Weld Discoloration

Discoloration of the weld can occur due to oxidation or contamination. Ensure proper gas coverage, clean the base metal surfaces, and avoid excessive heat input.

If you encounter any issues during MIG welding, don’t be discouraged. Take the time to diagnose the problem and apply the appropriate troubleshooting techniques. With practice and experience, you’ll become more adept at identifying and resolving welding issues.

Mig Welding Projects for Beginners

Now that you have a solid understanding of MIG welding, it’s time to put your skills to the test with some beginner-friendly projects. Here are a few ideas to get you started:

Metal Artwork

Create unique metal sculptures or wall art by welding together various metal pieces. Let your creativity flow and experiment with different shapes, sizes, and finishes.

Garden Decorations

Build sturdy garden trellises, flower pot stands, or ornamental fences using MIG welding. These projects not only enhance your garden but also provide an opportunity to practice different welding techniques.

Home Repairs

From fixing broken metal furniture to repairing metal gates or fences, MIG welding allows you to tackle various home repair projects with ease. Save money and give your DIY skills a boost by taking on these repairs yourself.

Metal Fabrication

Fabricate small metal components, brackets, or supports for DIY projects around the house. MIG welding gives you the ability to create custom metal parts to fit your specific needs.

Mig Welding vs Other Welding Processes

While MIG welding is a versatile and beginner-friendly welding process, it’s essential to understand how it compares to other welding processes. Here’s a brief comparison of MIG welding with other popular welding techniques:

Stick Welding (SMAW)

Stick welding is a versatile welding process that can be used for various materials and in different positions. It requires minimal equipment setup and can be used in outdoor and remote environments. Stick welding is slower compared to MIG welding and produces more spatter.

TIG Welding (GTAW)

TIG welding offers precise control and produces clean and aesthetically pleasing welds. It is commonly used for welding thin materials and non-ferrous metals. TIG welding is slower and more complex than MIG welding, requiring higher skill levels and more equipment.

Flux-Cored Arc Welding (FCAW)

Flux-cored arc welding is similar to MIG welding but uses a tubular flux-core wire instead of a solid wire electrode. It offers better penetration and works well in outdoor or windy conditions. It produces more smoke and requires different shielding gas and wire types.

Each welding process has its own advantages and is suitable for specific applications. It’s important to understand the strengths and limitations of each process to choose the most appropriate one for your specific welding needs.

Conclusion

MIG welding is a versatile and efficient welding technique that is suitable for beginners and professionals alike. It offers several advantages, including the ability to weld a wide range of metals, fast welding speeds, and ease of use. By understanding the equipment, safety precautions, and proper techniques and settings, beginners can confidently embark on their MIG welding journey.

Whether you’re interested in DIY projects or pursuing a career in welding, MIG welding is a valuable skill to master. So, let’s get started on your path to becoming a proficient MIG welder!

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.