Whether you’re a novice welder just starting out or an experienced professional looking to brush up on your skills, mastering pipe welding techniques is essential for success in the industry. From joining pipes for plumbing systems to fabricating structures for oil and gas pipelines, pipe welding plays a crucial role in a wide range of applications.

We will explore various pipe welding techniques that are commonly used in the industry. From the classic Shielded Metal Arc Welding (SMAW) to the more advanced Gas Tungsten Arc Welding (GTAW) and Flux-Cored Arc Welding (FCAW), we will delve into the nuances of each technique, discussing their advantages and limitations. We will also provide practical tips and guidelines to help you improve your welding skills and ensure strong, durable welds.

Image by Faustgen

Different types of welding techniques used in pipe welding

Pipe welding involves the joining of pipes using different welding techniques. The choice of technique depends on factors such as the type of pipe material, the application, and the desired strength of the weld. Some of the commonly used pipe welding techniques include:

Shielded Metal Arc Welding (SMAW)

Also known as stick welding, SMAW is one of the oldest and most versatile welding techniques. It uses a consumable electrode coated in flux to create an arc and form the weld. SMAW is commonly used in construction, maintenance, and repair work due to its simplicity and ability to work with various metals.

Gas Tungsten Arc Welding (GTAW)

Also known as Tungsten Inert Gas (TIG) welding, GTAW is a precise and high-quality welding technique. It uses a non-consumable tungsten electrode and an inert gas, such as argon, to create a weld. GTAW produces clean and visually appealing welds, making it ideal for applications where aesthetics are important, such as food processing equipment and aerospace components.

Flux-Cored Arc Welding (FCAW)

FCAW is a semi-automatic welding technique that uses a continuously fed tubular electrode filled with flux. The flux provides a shielding gas and forms a slag that protects the weld from atmospheric contamination. FCAW is commonly used in heavy structural welding and in situations where high deposition rates are required.

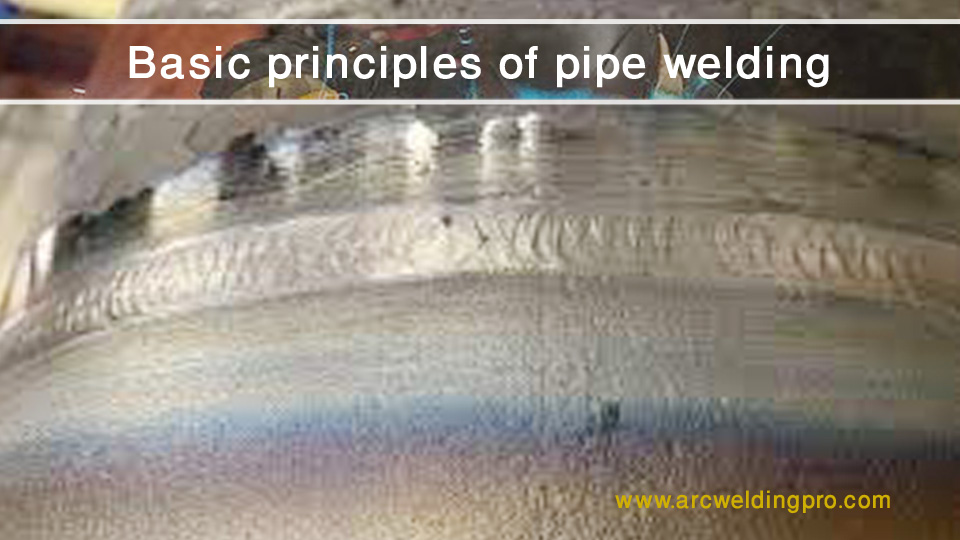

Basic principles of pipe welding

To achieve strong and durable welds, it is important to understand the basic principles of pipe welding. These principles apply to all welding techniques and can help ensure the integrity of the weld. Here are the key principles to keep in mind:

Cleanliness

Before starting the welding process, it is crucial to clean the pipes thoroughly to remove any dirt, grease, or contaminants. This can be done using a wire brush or a chemical cleaner. Clean pipes ensure better fusion and reduce the risk of defects in the weld.

Joint preparation

Proper joint preparation is essential for a successful weld. The type of joint used depends on the application and the welding technique. Common types of joints include butt joints, lap joints, and tee joints. The edges of the pipes should be properly beveled or squared before welding to ensure proper penetration and fusion.

Heat control

Controlling the heat during welding is critical to prevent overheating or underheating of the pipes. The heat input should be adjusted according to the pipe material and thickness. Excessive heat can lead to distortion, while insufficient heat can result in weak welds. It is important to maintain a consistent and appropriate heat throughout the welding process.

Image by Reddit

Common challenges in pipe welding and how to overcome them

Pipe welding can present various challenges that can affect the quality of the weld. Understanding these challenges and knowing how to overcome them is crucial for achieving strong and reliable welds. Some common challenges in pipe welding include:

Pipe alignment

Proper alignment of the pipes is essential for a successful weld. Misalignment can lead to uneven fusion and weak welds. The use of clamps, fixtures, and tack welds can help ensure proper alignment before welding.

Joint fit-up

Achieving a tight fit-up between the pipes is important to ensure full penetration and fusion. Gaps or uneven fit-up can result in defects in the weld. Proper joint preparation, including beveling and squaring the edges, can help achieve a good fit-up.

Welding position

Pipe welding often requires working in different positions, such as horizontal, vertical, or overhead. Each position presents its own challenges, including gravity affecting the weld pool and difficulty in accessing the joint. Proper technique, positioning, and the use of appropriate welding equipment can help overcome these challenges.

To overcome these challenges, it is important to practice and develop good welding techniques. Regularly inspecting and testing the welds can also help identify any defects or issues and take corrective measures.

Safety precautions in pipe welding

Pipe welding involves working with high temperatures, electricity, and potentially hazardous materials. Therefore, it is crucial to follow safety precautions to protect yourself and others from accidents and injuries. Here are some important safety precautions to observe during pipe welding:

Personal protective equipment (PPE)

Always wear the appropriate PPE, including welding gloves, a welding helmet with a proper lens shade, flame-resistant clothing, and safety glasses. PPE helps protect against burns, sparks, and harmful radiation emitted during welding.

Ventilation

Ensure proper ventilation in the welding area to remove fumes and gases generated during welding. Welding in a confined space or without adequate ventilation can lead to the accumulation of toxic fumes, which can be hazardous to health.

Fire prevention

Keep a fire extinguisher nearby and ensure the welding area is free from flammable materials. Sparks or hot metal can ignite nearby combustible materials, leading to fire hazards. Taking precautions such as removing flammable materials and having fire safety measures in place can help prevent accidents.

Electrical safety

Ensure that the welding equipment is properly grounded and in good working condition. Inspect the cables and connections regularly for any damages. Avoid welding near water or wet surfaces to minimize the risk of electric shock.

By following these safety precautions, you can create a safe working environment and minimize the risks associated with pipe welding.

Image by thefabricator

Equipment and tools required for pipe welding

To perform pipe welding, you will need a range of equipment and tools. The specific requirements may vary depending on the welding technique and the project at hand. However, here are some essential equipment and tools commonly used in pipe welding:

Welding machine

A welding machine is the primary tool used for pipe welding. The type of welding machine depends on the welding technique being used. For example, SMAW requires a welding machine that can provide a direct current (DC) output, while GTAW requires a machine capable of providing alternating current (AC) or DC output.

Electrodes or filler wires

Depending on the welding technique, you will need either electrodes or filler wires. Electrodes are used in SMAW, while filler wires are used in GTAW and FCAW. These consumable materials provide the necessary filler metal to create the weld.

Welding helmet

A welding helmet is essential for protecting your eyes and face from the intense light and sparks generated during welding. Choose a helmet with a proper lens shade that suits the welding technique and the current intensity.

Welding gloves

Welding gloves provide heat and electrical insulation, protecting your hands from burns and electric shock. Opt for gloves made from flame-resistant materials, such as leather or Kevlar, for maximum protection.

Clamps and fixtures

Clamps and fixtures are used to hold the pipes in position during welding. They help ensure proper alignment and fit-up, resulting in high-quality welds. Different types of clamps and fixtures are available, depending on the pipe diameter and welding technique.

Grinding tools

Grinding tools, such as angle grinders and wire brushes, are used for cleaning and preparing the pipes before welding. They help remove any rust, scale, or contaminants that can affect the quality of the weld.

Measuring tools

Accurate measurements are important for achieving proper joint fit-up. Measuring tools, such as tape measures and calipers, are essential for ensuring precise measurements and alignment of the pipes.

Having the right equipment and tools and keeping them well-maintained can greatly contribute to the success of your pipe welding projects.

Step-by-step guide to pipe welding

Now that we have discussed the different welding techniques, basic principles, challenges, safety precautions, and equipment required for pipe welding, let’s dive into a step-by-step guide to help you get started with pipe welding:

Step 1: Prepare the pipes

Thoroughly clean the pipes using a wire brush or chemical cleaner to remove any dirt, grease, or contaminants. Bevel or square the edges of the pipes for proper joint fit-up.

Step 2: Position the pipes

Use clamps, fixtures, or tack welds to ensure proper alignment and fit-up of the pipes. Check for any gaps or misalignment and make adjustments as needed.

Step 3: Set up the welding machine

Select the appropriate welding machine and set the parameters according to the pipe material, thickness, and welding technique. Refer to the manufacturer’s guidelines for specific settings.

Step 4: Start the arc

Strike an arc by touching the electrode or filler wire to the pipe and quickly pulling it back to establish an arc. Maintain the appropriate arc length and angle to ensure proper heat input and penetration.

Step 5: Weld the joint

Move the electrode or filler wire along the joint, maintaining a steady travel speed and consistent heat input. Ensure proper fusion and penetration by observing the weld pool and adjusting the technique as needed.

Step 6: Complete the weld

Continue welding along the joint until the desired length is achieved. Allow the weld to cool gradually to prevent cracking or distortion.

Step 7: Inspect the weld

Once the weld has cooled, inspect it visually and, if necessary, perform non-destructive testing (NDT) to ensure the weld’s integrity. Look for any defects, such as cracks or porosity, and take corrective measures if required.

By following these steps and practicing regularly, you can improve your pipe welding skills and achieve high-quality welds.

Image by uti edu

Tips for achieving high-quality pipe welds

To achieve high-quality pipe welds, consider the following tips:

Practice proper technique

Mastering proper welding technique is crucial for achieving strong and durable welds. Practice maintaining the appropriate arc length, travel speed, and heat input for each welding technique.

Control the heat

Proper heat control is essential for preventing overheating or underheating of the pipes. Adjust the heat input according to the pipe material and thickness to achieve optimal fusion and penetration.

Use the right filler material

Select the appropriate filler material based on the pipe material and the welding technique. Using the correct filler material ensures compatibility and proper fusion with the base metal.

Inspect and test the welds

Regularly inspect and test the welds to identify any defects or issues. Perform visual inspections and, if necessary, use non-destructive testing methods such as ultrasonic testing or radiographic testing to ensure the weld’s integrity.

Seek guidance from experts

If you’re a beginner or facing challenges in pipe welding, seek guidance from experienced welders or attend training programs. Learning from experts can help improve your skills and provide valuable insights.

Achieving high-quality pipe welds requires practice, patience, and continuous learning. Be open to feedback and strive to improve your skills with each project.

Advanced pipe welding techniques

In addition to the basic pipe welding techniques discussed earlier, there are advanced techniques that offer specialized capabilities for specific applications. These techniques require additional training and expertise but can greatly enhance your pipe welding skills. Here are a few advanced pipe welding techniques:

Orbital welding

Orbital welding is an automated welding technique that uses a rotating electrode to create a continuous weld. It is commonly used in industries such as semiconductor manufacturing, pharmaceuticals, and food processing, where precise and high-quality welds are required.

Laser welding

Laser welding uses a high-energy laser beam to melt and fuse the base metal. It offers high precision, speed, and control, making it suitable for applications where fine welding control is required, such as medical devices and electronics.

Electron beam welding (EBW)

EBW uses a focused beam of high-velocity electrons to create a weld. It offers deep penetration and narrow heat-affected zones, making it ideal for joining thick-walled pipes or dissimilar materials. EBW is commonly used in aerospace, automotive, and nuclear industries.

These advanced techniques require specialized equipment and training. If you’re interested in exploring these techniques, consider seeking additional training and guidance from experts in the field.

Conclusion

Mastering pipe welding techniques is a valuable skill that opens up opportunities in various industries. Whether you’re interested in pursuing a career in welding or simply want to tackle pipe welding projects for personal use, understanding the different techniques, principles, and safety precautions is essential.

We explored the different types of pipe welding techniques, the basic principles of pipe welding, common challenges, safety precautions, and the equipment required. We also provided a step-by-step guide to help you get started with pipe welding and shared tips for achieving high-quality welds.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.