Selecting the right tungsten electrode size is crucial for achieving optimal arc performance, penetration control, and arc stability in welding applications. The size of the tungsten electrode directly impacts the welding current, arc characteristics, and overall weld quality. This guide will walk you through the key factors to consider when choosing the appropriate tungsten electrode size for your specific welding needs.

Tungsten Electrode Sizing

The selection of the proper tungsten electrode size is a crucial factor in achieving optimal welding performance, arc stability, and weld quality. Two key considerations in this process are the electrode diameter and the extension length.

Electrode Diameter and Welding Current

The diameter of the tungsten electrode directly correlates to the welding current. Larger diameter electrodes, such as those measuring 3/32″ or 1/8″, are capable of handling higher welding currents, making them suitable for thicker workpieces and more demanding applications. Conversely, smaller electrodes, typically 1/16″ or 3/64″, are better suited for lower current ranges, often used in precision welding or on thinner materials.

Electrode Extension Length

The electrode extension length, also known as the exposed length of the tungsten protruding from the torch, plays a significant role in the arc characteristics and stability. Longer extension lengths can lead to increased electrode heating and the potential for wandering arcs, which can compromise weld consistency and quality.

On the other hand, shorter extension lengths may result in inadequate arc shielding and decreased weld penetration. Striking the right balance in electrode extension length is crucial for maintaining a stable, focused arc and achieving the desired weld outcomes.

Factors Influencing Tungsten Electrode Size Selection

When selecting the appropriate tungsten electrode size, it’s crucial to consider the specific welding application, the materials being joined, the joint configuration, accessibility, and the welding position and technique. These factors will significantly influence the optimal electrode size to ensure optimal arc performance, penetration control, and weld quality.

Welding Application and Materials

The thickness and type of the workpiece, as well as the desired weld penetration and bead width, will determine the most suitable tungsten electrode size. For example, thicker materials may require a larger electrode diameter to handle the increased welding current needed for deeper penetration, while thinner materials may call for a smaller electrode to maintain control and avoid excessive weld penetration.

Joint Configuration and Accessibility

The joint configuration, such as butt, fillet, or corner welds, and the accessibility of the joint can also impact the tungsten electrode size selection. Tight or hard-to-reach joints may necessitate a smaller electrode diameter to ensure proper arc control and stability, whereas more accessible joints may accommodate larger electrodes.

Welding Position and Technique

The welding position, be it flat, horizontal, or overhead, can influence the tungsten electrode size choice. Certain positions may require a smaller electrode to maintain arc control and prevent wandering or instability. The welding technique, such as GTAW (TIG) or GMAW (MIG), can also factor into the optimal electrode size selection.

Tungsten Electrode Classification System

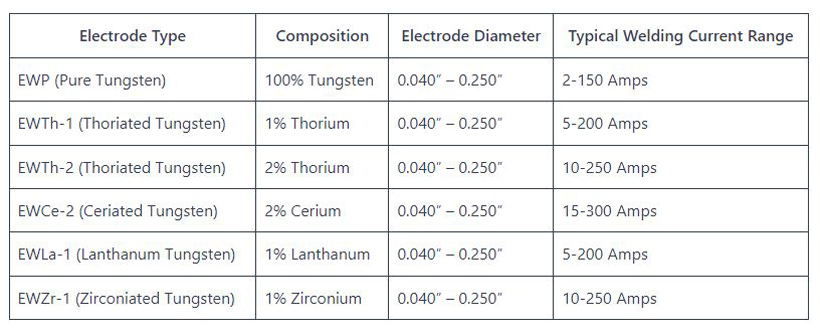

The tungsten electrode classification system provides a standardized guide for identifying the appropriate electrode size and composition based on the intended welding application. This system takes into account factors such as the electrode diameter, composition (pure tungsten or thoriated), and color coding for easy identification. Understanding this classification system can greatly assist in selecting the correct welding electrode for your specific needs.

The classification system is based on the American Welding Society (AWS) A5.12 standard, which outlines the various types of tungsten electrodes and their corresponding characteristics. By referencing this system, welders can easily determine the optimal electrode size and composition for their welding process, ensuring optimal arc performance, penetration control, and overall weld quality.

| Electrode Type | Composition | Electrode Diameter | Typical Welding Current Range |

|---|---|---|---|

| EWP (Pure Tungsten) | 100% Tungsten | 0.040″ – 0.250″ | 2-150 Amps |

| EWTh-1 (Thoriated Tungsten) | 1% Thorium | 0.040″ – 0.250″ | 5-200 Amps |

| EWTh-2 (Thoriated Tungsten) | 2% Thorium | 0.040″ – 0.250″ | 10-250 Amps |

| EWCe-2 (Ceriated Tungsten) | 2% Cerium | 0.040″ – 0.250″ | 15-300 Amps |

| EWLa-1 (Lanthanum Tungsten) | 1% Lanthanum | 0.040″ – 0.250″ | 5-200 Amps |

| EWZr-1 (Zirconiated Tungsten) | 1% Zirconium | 0.040″ – 0.250″ | 10-250 Amps |

By understanding this tungsten electrode classification system, welders can make informed decisions when selecting the appropriate electrode size and composition for their specific welding application, ensuring optimal arc stability, penetration control, and overall weld quality.

Preparing and Sharpening Tungsten Electrodes

Proper preparation and maintenance of tungsten electrodes are crucial for maintaining arc stability and optimal welding performance. This involves carefully sharpening the electrode tip to the appropriate shape and length, as well as ensuring the electrode is free from any contaminants that could disrupt the arc.

Proper Electrode Preparation Methods

To achieve the best results, it’s important to follow proper electrode preparation techniques. This includes using a dedicated tungsten grinder or a fine-grit abrasive wheel to sharpen the electrode to the desired point. The angle and length of the sharpened tip should be tailored to the specific welding application and current requirements. Maintaining a consistent, uniform shape on the electrode tip is essential for creating a stable, focused arc.

Avoiding Electrode Contamination

Contaminants on the surface of the tungsten electrode can significantly impact arc stability and welding performance. It’s crucial to handle the electrodes with care, avoiding any contact with oils, grease, or other foreign substances that could disrupt the arc. Regularly cleaning the electrodes with a clean, lint-free cloth and properly storing them in a dedicated container can help prevent contamination and ensure reliable, consistent welds.

Conclusion

The selection of the correct tungsten electrode size is vital for achieving optimal welding performance, arc stability, and weld quality. The selection process involves key factors such as electrode diameter and extension length, which directly influence the welding current and arc characteristics.

The specific welding application, workpiece materials, joint configuration, accessibility, and the welding position and technique also significantly influence the appropriate electrode size selection.

The tungsten electrode classification system, based on the American Welding Society (AWS) A5.12 standard, provides a useful guide for identifying the suitable electrode size and composition. Proper preparation and maintenance of tungsten electrodes, including sharpening and avoiding contamination, are critical for maintaining arc stability and optimal welding performance.

FAQ

What factors should I consider when selecting the right tungsten electrode size?

When selecting the appropriate tungsten electrode size, you should consider the welding application, materials being joined, joint configuration, accessibility, and the welding position and technique. The thickness and type of the workpiece, desired weld penetration and bead width, and the welding position (flat, horizontal, or overhead) will all influence the optimal electrode size.

How does the tungsten electrode diameter relate to the welding current?

The diameter of the tungsten electrode is directly related to the welding current. Larger diameter electrodes can handle higher welding currents, while smaller electrodes are suitable for lower current ranges. Choosing the correct electrode diameter for the desired welding current is crucial for achieving optimal arc performance and weld quality.

What is the importance of the tungsten electrode extension length?

The electrode extension length, or the exposed length of the electrode protruding from the torch, plays a significant role in arc characteristics and stability. Longer extension lengths can lead to increased electrode heating and potential for wandering arcs, while shorter extensions may result in inadequate arc shielding and decreased weld penetration. Proper adjustment of the extension length is essential for maintaining a stable and focused arc.

How do I prepare and sharpen tungsten electrodes for optimal welding performance?

Proper preparation and maintenance of tungsten electrodes are crucial for maintaining arc stability and optimal welding performance. This includes accurately sharpening the electrode tip to the appropriate shape and length, as well as ensuring the electrode is free from any contaminants that could disrupt the arc. Paying close attention to these details can help extend the lifespan of the electrode and ensure consistent, high-quality welds.

What is the tungsten electrode classification system and how does it help in selecting the right size?

The tungsten electrode classification system provides a standardized guide for identifying the appropriate electrode size and composition based on the intended welding application.

This system takes into account factors such as the electrode diameter, composition (pure tungsten or thoriated), and color coding for easy identification. This classification system can greatly assist in selecting the correct tungsten electrode for your specific welding needs.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.