Have you ever wondered which shielding gas can boost the penetration of your flux-cored arc welding (FCAW) process? In this article, we will explore the various shielding gases available and their impact on weld penetration. Choosing the right shielding gas is essential to ensure quality and strength in your FCAW welds. We will delve into the factors that affect weld penetration, including the gas composition, flow rate, and nozzle design.

Whether you’re a seasoned welder or just starting out, understanding how different shielding gases influence weld penetration can greatly improve your welding efficiency and output. Let’s dig deeper into the world of FCAW welding and discover which shielding gas can take your welds to the next level.

Photo by halversoncts

Shielding Gas in FCAW Welding

Shielding gas plays a crucial role in FCAW welding by protecting the weld pool from atmospheric contamination. It prevents oxygen, nitrogen, and other elements from reacting with the molten metal, which could result in defects like porosity and lack of fusion. The primary function of shielding gas is to create a stable arc and promote good penetration.

Weld Penetration in FCAW Welding

Weld penetration refers to the depth to which the weld filler metal penetrates the base metal. It is a critical aspect of welding, as it directly affects the strength and integrity of the joint. Achieving adequate penetration ensures a sound weld that can withstand the required load and stress.

Common Shielding Gases Used in FCAW Welding

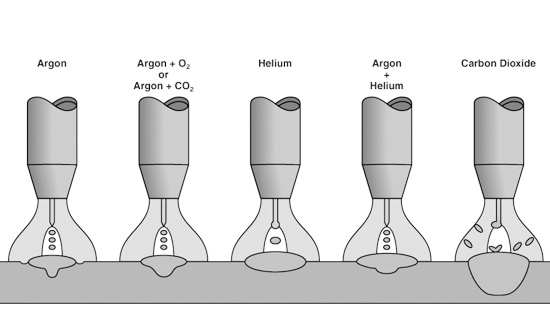

There are several types of shielding gases used in FCAW welding, each with its own characteristics and benefits. The most commonly used gases include pure carbon dioxide (CO2), argon, and mixtures of argon and CO2. Let’s explore each of these options in more detail:

Pure Carbon Dioxide (CO2)

CO2 is a popular choice for FCAW welding due to its affordability and availability. It provides deep penetration, making it suitable for welding thick materials. CO2 can result in increased spatter and a less stable arc compared to other gases.

Argon

Argon is an inert gas that offers excellent arc stability and reduced spatter. It promotes good weld penetration and is often used in combination with CO2 for improved results. However, argon can be more expensive than CO2, making it less cost-effective for some applications.

Argon-CO2 Mixtures

Mixing argon with CO2 allows for a balance between deep penetration and arc stability. The ratio of argon to CO2 can be adjusted to achieve the desired welding characteristics. Argon-CO2 mixtures are versatile and widely used in various welding applications.

Comparing Different Shielding Gases for Weld Penetration

When selecting a shielding gas for FCAW welding, it is essential to consider the desired weld penetration and the specific requirements of the project. Here is a comparison of the different shielding gases in terms of their impact on weld penetration:

Pure CO2

Provides deep penetration, making it suitable for welding thicker materials. It can result in increased spatter and a less stable arc.

Argon

Offers good penetration and arc stability. Produces less spatter compared to CO2. Can be more expensive than CO2.

Argon-CO2 Mixtures

Allows for a balance between penetration and arc stability. The ratio of argon to CO2 can be adjusted based on specific welding requirements. Provides versatility and improved results in various applications.

Factors to Consider When Choosing a Shielding Gas for FCAW Welding

When deciding on the most appropriate shielding gas for FCAW welding, several factors should be taken into account:

Material Thickness

Thicker materials generally require a shielding gas that provides deeper penetration, such as pure CO2. Thinner materials may benefit from a gas mixture that offers better arc stability and reduced spatter.

Welding Position

Different shielding gases perform differently based on the welding position (e.g., flat, horizontal, vertical). Some gases may provide better penetration in certain positions, while others offer improved arc control.

Cost

The cost of the shielding gas can vary depending on availability and market conditions. It is essential to consider the project budget and weigh the benefits against the cost when selecting a gas.

Welding Speed

Higher welding speeds may require a shielding gas that provides better arc stability to maintain penetration.

Best Practices for Using Shielding Gases in FCAW Welding

To achieve optimal weld penetration with shielding gases in FCAW welding, it is crucial to follow these best practices:

Proper Gas Flow Rate

Ensure the correct gas flow rate based on the manufacturer’s recommendations. Insufficient gas flow can lead to inadequate shielding and reduced weld quality.

Electrode Stickout

Maintain the appropriate electrode stickout to ensure proper gas coverage and penetration. The stickout refers to the length of the wire extending beyond the contact tip.

Welding Technique

Use the correct welding technique, including the travel speed, angle, and manipulation of the welding gun. Proper technique helps maintain consistent arc length and improves weld penetration.

Testing and Evaluating Weld Penetration with Different Shielding Gases

To determine the effectiveness of different shielding gases in achieving weld penetration, it is crucial to conduct testing and evaluation. This can be done by performing sample welds using various gases and assessing the resulting penetration depth, weld quality, and overall performance.

Industry Standards and Regulations for Shielding Gas Use in FCAW Welding

It is essential to adhere to industry standards and regulations when using shielding gases in FCAW welding. These standards ensure the safety of the welding process and help maintain consistent quality. Familiarize yourself with the relevant guidelines and follow proper procedures for gas selection, handling, and storage.

Conclusion

The choice of shielding gas in FCAW welding significantly impacts weld penetration and overall weld quality. Depending on the specific requirements of the project, different gases offer unique advantages and limitations. Consider factors such as material thickness, welding position, cost, and welding speed when selecting the most suitable shielding gas.

To enhance weld penetration, it is crucial to follow best practices, maintain proper gas flow rate, electrode stickout, and employ the correct welding techniques. Regular testing and evaluation can help optimize welding results and identify the most suitable shielding gas for specific applications.

By understanding the impact of different shielding gases on weld penetration and following recommended practices, welders can achieve superior results and produce strong, reliable welds in their FCAW projects.

Selecting the right shielding gas is not just about achieving weld penetration; it’s about ensuring the longevity and quality of the weld. Take the time to evaluate your welding needs and make informed decisions when choosing the appropriate shielding gas for your FCAW welding projects.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.