As a professional welder, I have always been fascinated by the art of TIG welding aluminum. The precision and elegance of this process have always intrigued me. Over the years, I have honed my skills and experimented with various techniques.

One particular area that has caught my attention is TIG welding aluminum without filler. W will take you through the journey of mastering this art, exploring the possibilities, and understanding the benefits and limitations.

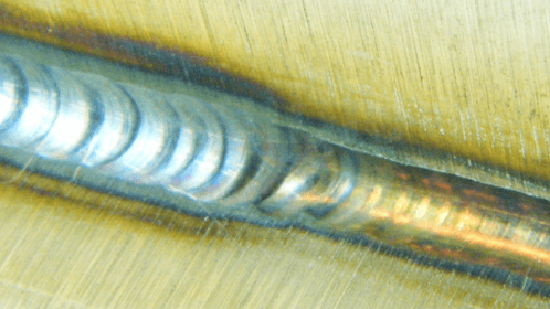

Photo by metfab.com.au

Benefits and Limitations

TIG welding aluminum without filler offers several advantages over traditional welding methods. One of the key benefits is the elimination of additional material, resulting in a cleaner and more aesthetically pleasing weld. This is particularly useful when working on projects that require a high level of precision and cleanliness, such as aerospace components or architectural structures.

However, it is important to note that TIG welding aluminum without filler also has its limitations. The absence of filler material means that the weld may not have the same strength as a weld created with filler. This makes it less suitable for applications that require high load-bearing capacity.

The lack of filler material can make welding thinner aluminum sheets more challenging, as the heat generated during the welding process can cause warping and distortion.

Techniques for TIG Welding Aluminum Without Filler

To achieve successful TIG welding of aluminum without filler, it is crucial to master the right techniques. One of the key techniques is maintaining a steady hand and a consistent travel speed. This helps in preventing overheating and ensures a uniform weld. Additionally, using a small diameter tungsten electrode with a pointed tip allows for better control and precision.

Another important technique is the use of a high-frequency start. This helps in initiating the arc without the need for direct contact between the electrode and the workpiece. It is also essential to maintain a proper balance of the AC waveforms to control the heat input and prevent excess penetration.

Preparing the Aluminum Surface for Welding

Before diving into the welding process, it is crucial to prepare the aluminum surface properly. This involves thorough cleaning and removal of any contaminants such as oil, grease, or oxidation. A dedicated aluminum cleaner or a mixture of acetone and a non-abrasive detergent can be used for this purpose. It is recommended to use a stainless steel wire brush to remove any surface oxides and create a clean surface for welding.

Once the surface is clean, it is important to ensure proper fit-up and alignment of the pieces to be welded. This can be achieved by using clamps or fixtures to hold the pieces in place. Proper fit-up ensures a tight joint and minimizes the chances of gaps or misalignment, which can result in weaker welds.

Choosing the Right TIG Welding Machine and Settings

To achieve optimal results in TIG welding aluminum without filler, it is crucial to choose the right welding machine and settings. When selecting a welding machine, look for one that offers both AC and DC output capabilities. AC is used for cleaning the oxide layer on the aluminum surface, while DC is used for the actual welding process.

In terms of settings, it is important to adjust the balance control to achieve the desired cleaning action. A higher balance control setting results in more cleaning action, while a lower setting provides better penetration. Adjusting the frequency control can help in controlling the width of the arc and the heat input.

Safety Precautions for TIG Welding Aluminum Without Filler

Like any welding process, TIG welding aluminum without filler requires proper safety precautions to be followed. One of the key safety measures is the use of personal protective equipment (PPE). This includes wearing a welding helmet with a shaded lens, welding gloves, a flame-resistant jacket, and safety glasses.

It is also important to ensure proper ventilation in the welding area to prevent the buildup of harmful fumes and gases. This can be achieved by using exhaust fans or working in a well-ventilated space. It is crucial to have a fire extinguisher nearby and to be aware of the location of emergency exits.

Common Challenges and Troubleshooting Tips

TIG welding aluminum without filler can present some challenges, but with the right knowledge and troubleshooting tips, these challenges can be overcome. One common challenge is the formation of a black sooty residue on the surface of the weld. This can be caused by insufficient shielding gas coverage or excessive heat input. Increasing the flow rate of the shielding gas and adjusting the balance control can help in resolving this issue.

Another challenge is the formation of cracks in the weld. This can be caused by excessive heat or improper fit-up. To prevent cracks, it is important to maintain a steady travel speed and ensure proper fit-up and alignment of the pieces to be welded.

Examples of Projects Suited for TIG Welding Aluminum Without Filler

TIG welding aluminum without filler opens up a world of possibilities for various projects. One such example is the fabrication of aluminum artwork or sculptures. The clean and precise welds achieved through this process can enhance the aesthetic appeal of the final piece. Another example is the construction of lightweight aluminum furniture, where the absence of filler material ensures a seamless and elegant design.

Comparing TIG Welding with and Without Filler

While TIG welding aluminum without filler offers its own set of advantages, it is important to compare it with traditional TIG welding using filler material. TIG welding with filler provides stronger and more durable welds, making it suitable for applications that require high load-bearing capacity.

TIG welding with filler allows for easier welding of thicker aluminum sheets, as the filler material helps in dissipating the heat and reducing the chances of warping.

Conclusion

TIG welding aluminum without filler offers a range of possibilities and benefits. It is a technique that requires skill, precision, and attention to detail. While it may not be suitable for all applications, it is a valuable skill to have in your welding repertoire.

If you are a professional welder or a hobbyist, exploring the possibilities of TIG welding aluminum without filler can open up new avenues for creativity and innovation.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.