Tig welding aluminum without gas is a technique that requires skill and precision. It is a popular method for joining aluminum because it produces clean, high-quality welds. We will take you through the process of Tig welding aluminum without gas, from understanding the advantages and disadvantages to choosing the right equipment and troubleshooting common issues.

Photo by metalworkmasters

Advantages and disadvantages of Tig welding aluminum without gas

Tig welding aluminum without gas offers several advantages over other welding methods. One of the main advantages is the ability to create clean, high-quality welds. The absence of gas eliminates the need for a shielding gas, reducing the overall cost of the welding process. Tig welding aluminum without gas allows for greater control and precision, making it ideal for intricate projects.

There are also some disadvantages to Tig welding aluminum without gas. One of the main challenges is the increased risk of oxidation. Without a shielding gas, the weld is exposed to the air, which can lead to oxidation and poor weld quality. Additionally, Tig welding aluminum without gas requires a higher skill level and more experience compared to other welding methods.

Process of Tig welding aluminum without gas

To understand the process of Tig welding aluminum without gas, it is important to have a basic understanding of how Tig welding works. Tig welding, also known as Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to create an electric arc that melts the base material and filler material (if used) to form a weld.

When Tig welding aluminum without gas, the absence of a shielding gas means that the weld is exposed to the air. To prevent oxidation and ensure a clean weld, it is important to use a technique called “scratch start.” This involves quickly scratching the surface of the aluminum with the tungsten electrode to remove any oxidation before starting the weld.

Safety precautions for Tig welding aluminum without gas

As with any welding process, safety is of utmost importance when Tig welding aluminum without gas. Here are some important safety precautions to keep in mind:

- Wear protective clothing: Always wear a welding helmet, gloves, and a flame-resistant jacket or apron to protect yourself from sparks and heat.

- Ensure proper ventilation: Tig welding produces fumes and gases that can be harmful if inhaled. Make sure you are working in a well-ventilated area or use an exhaust system to remove the fumes.

- Protect your eyes: Use a welding helmet with a darkened lens to protect your eyes from the intense light produced during the welding process.

- Handle equipment with care: Tig welding equipment can be dangerous if mishandled. Always follow the manufacturer’s instructions and handle the equipment with care to prevent accidents.

Choosing the right equipment for Tig welding aluminum without gas

Choosing the right equipment is crucial for successful Tig welding aluminum without gas. Here are some factors to consider when selecting your equipment:

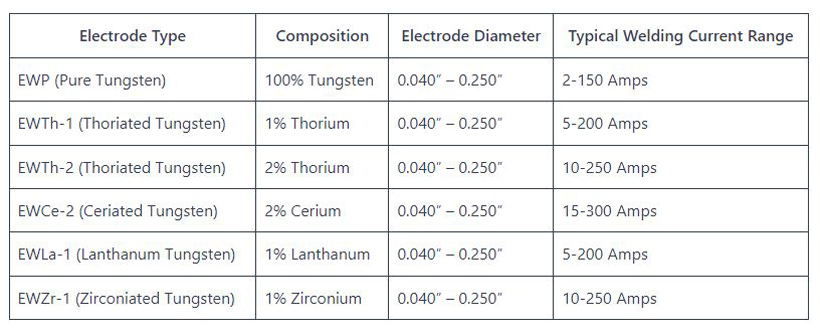

Tungsten electrode: Use a pure tungsten electrode for Tig welding aluminum. Pure tungsten has a higher melting point and provides better arc stability.

Power source: Select a Tig welding machine with a high-frequency start feature. This will help you achieve a stable arc and prevent contamination of the weld.

Filler material: If necessary, choose a filler material that is compatible with aluminum. Common filler materials for aluminum include 4043 and 5356.

Gas lens: While Tig welding aluminum without gas, using a gas lens can help improve shielding and reduce the risk of oxidation. A gas lens directs the flow of shielding gas to the weld area, creating a more stable arc and cleaner weld.

Preparing the aluminum surface for Tig welding without gas

Proper preparation of the aluminum surface is essential for successful Tig welding without gas. Here are some steps to follow:

Clean the surface: Use a wire brush or sandpaper to remove any dirt, oil, or oxidation from the surface of the aluminum. This will ensure a clean weld and minimize the risk of contamination.

Remove the oxide layer: Aluminum forms a thin oxide layer on its surface, which can interfere with the welding process. Use a stainless steel brush or chemical cleaner to remove the oxide layer before welding.

Deburr the edges: If the aluminum has sharp edges or burrs, use a file or grinder to smooth them out. This will help create a clean, even weld.

Secure the workpiece: Use clamps or magnets to secure the aluminum in position before welding. This will prevent movement and ensure accurate weld placement.

Techniques and tips for Tig welding aluminum without gas

Tig welding aluminum without gas requires specific techniques and tips to achieve high-quality welds. Here are some techniques and tips to keep in mind:

Control the heat

Aluminum has a high thermal conductivity, which means it dissipates heat quickly. To avoid overheating the material, use a lower amperage and maintain a shorter arc length.

Use a push technique

When Tig welding aluminum without gas, it is generally recommended to use a push technique. This involves pushing the torch away from the weld puddle, which helps prevent contamination and ensures a clean weld.

Maintain a consistent travel speed

To achieve a uniform weld bead, maintain a consistent travel speed. Too slow of a travel speed can lead to excessive heat input, while too fast of a travel speed can result in a shallow penetration.

Backpurge if necessary

If the weld joint allows for it, consider using a backing gas to prevent oxidation on the backside of the weld. This can help improve the overall quality of the weld.

Troubleshooting common issues in Tig welding aluminum without gas

Even with proper technique and preparation, issues can still arise during Tig welding aluminum without gas. Here are some common issues and their potential solutions:

Porosity

Porosity is the presence of small holes or voids in the weld. It is often caused by contamination or insufficient shielding. Check for proper cleaning and shielding gas flow.

Lack of fusion

Lack of fusion occurs when the weld fails to fully penetrate the base material. It can be caused by insufficient heat or improper technique. Increase the amperage or adjust your technique to ensure proper fusion.

Cracking

Cracking can occur if the weld cools too quickly or if there is excessive stress in the weld joint. Preheating the aluminum or using a slower cooling process can help prevent cracking.

Excessive spatter

Excessive spatter is the result of excessive heat or improper technique. Adjust the amperage or technique to reduce spatter.

Maintenance and care for Tig welding equipment used for aluminum without gas

Proper maintenance and care of your Tig welding equipment is essential for its longevity and performance. Here are some maintenance tips to keep in mind:

Clean the torch: Regularly clean the torch to remove any spatter or debris. This will help maintain proper gas flow and prevent contamination.

Inspect the tungsten electrode: Check the tungsten electrode regularly for signs of wear or damage. Replace it if necessary to ensure a stable arc.

Clean or replace the gas lens: If you are using a gas lens, clean or replace it regularly to maintain proper shielding gas flow.

Check cables and connections: Inspect the cables and connections for any signs of damage or wear. Replace any damaged parts to ensure proper electrical conductivity.

Conclusion

Tig welding aluminum without gas is a challenging but rewarding skill to master. By understanding the advantages and disadvantages, learning the proper techniques, and following safety precautions, you can achieve high-quality welds with ease.

Choose the right equipment, prepare the aluminum surface properly, and troubleshoot common issues as they arise. With practice and dedication, you will become proficient in the art of Tig welding aluminum without gas.?

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.