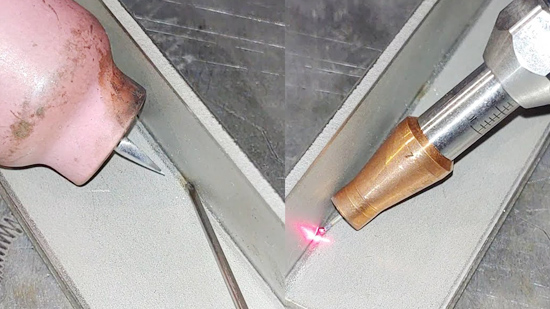

TIG welding and laser welding are both precise and efficient methods of joining metals. TIG welding uses a tungsten electrode to create the weld, while laser welding uses a focused beam of light. TIG welding offers versatility and control, making it suitable for a wide range of materials and thicknesses.

Laser welding provides high-speed, automated precision, making it ideal for intricate or complex designs. Both processes have their unique advantages and applications, and understanding the differences between TIG and laser welding can help in selecting the most suitable method for specific welding needs.

Photo by weldHAGOJIBI,YT

Tig Welding Vs Laser Welding: The Battle Of Precision

Tig Welding and Laser Welding are two popular methods known for their precise results in welding applications.

Key Differences

When comparing Tig Welding and Laser Welding, several key differences stand out:

- Tig Welding: Uses a tungsten electrode to create the weld, suitable for thicker materials.

- Laser Welding: Utilizes a high-powered laser beam for welding, ideal for intricate and delicate work.

Applications In Industry

Both Tig and Laser Welding find applications across various industries:

| Industry | Tig Welding | Laser Welding |

|---|---|---|

| Automotive | Frame assembly | Micro-welding of electronic components |

| Aerospace | Structural welding | Thin sheet metal welding |

| Medical | Equipment fabrication | Medical device manufacturing |

Basics Of Tig Welding

Tig welding and laser welding are two different processes used in metal fabrication. Tig welding uses a tungsten electrode to create the weld, while laser welding uses a high-powered laser beam. Both methods have their own advantages and limitations, so it’s important to consider the specific requirements of each project when choosing between the two.

Tig welding, also known as Gas Tungsten Arc Welding (GTAW), is a popular welding process that uses a non-consumable tungsten electrode to produce high-quality welds.

Tig welding is known for its precision and versatility, making it a popular choice for welding a wide range of materials, including aluminum, stainless steel, and titanium. In this section, we will explore the process and technique of Tig welding as well as the materials compatible with this welding process.

Process And Technique

Tig welding is a process that involves creating an arc between a non-consumable tungsten electrode and the workpiece. The arc is used to heat the workpiece and melt the metal, which then fuses together to create a strong, durable weld. Tig welding is a manual welding process that requires the welder to have a steady hand and good eye-hand coordination.

The welder controls the welding torch with one hand and feeds the filler material with the other hand. Tig welding requires a high degree of skill and precision, making it a popular choice for welding intricate or detailed parts. Tig welding is also known for producing clean, high-quality welds with minimal spatter or distortion.

Materials Compatible

Tig welding is compatible with a wide range of materials, including aluminum, stainless steel, titanium, copper, and brass. Tig welding is particularly well-suited for welding thin materials, as it produces a narrow, precise weld bead that minimizes heat distortion.

When welding aluminum, Tig welding is the preferred method due to its ability to produce high-quality welds with minimal distortion. Tig welding is also commonly used for welding stainless steel, as it produces a clean, precise weld with minimal spatter.

Tig welding is a popular welding process that offers precision, versatility, and high-quality welds. With the ability to weld a wide range of materials and produce clean, precise welds, Tig welding is a valuable skill for any welder to have.

Laser Welding Unveiled

Laser welding is a cutting-edge joining method that has revolutionized the manufacturing industry. Unlike traditional methods like TIG welding, laser welding harnesses the power of a concentrated beam of light to create precise and high-quality welds. We will unveil the fundamentals of laser welding and explore the materials best suited for this advanced process.

Fundamentals Of Laser Welding

Laser welding operates by focusing a concentrated beam of light onto the workpiece. The intense heat generated rapidly melts and fuses the materials together, resulting in a strong and precise weld. This process offers exceptional control and accuracy, making it ideal for intricate and delicate applications.

Materials Suited For Laser Welding

Laser welding is particularly well-suited for welding thin and delicate materials such as stainless steel, aluminum, and titanium. Its precise and low-heat input nature minimizes distortion and damage to the surrounding areas, making it an excellent choice for joining dissimilar metals and heat-sensitive components.

Comparative Analysis Of Weld Strength

When it comes to welding, the strength of the weld is a critical factor in determining the quality and durability of the finished product. Tig welding and laser welding are two popular welding methods, each with its own set of strength factors that contribute to the overall weld strength. We will delve into the specific strength factors associated with each welding method to gain a comprehensive understanding of their weld strength capabilities.

Tig Welding Strength Factors

Tig welding, also known as Gas Tungsten Arc Welding (GTAW), offers several key factors that contribute to the strength of the weld. These factors include:

- Ability to weld a wide range of metals including stainless steel, aluminum, and copper.

- Controlled heat input leading to minimal distortion and strong, high-quality welds.

- Excellent weld bead appearance and smooth finish, indicating strong fusion and uniformity.

Laser Welding Strength Factors

Laser welding, on the other hand, possesses distinct strength factors that contribute to its weld strength. These factors include:

- High welding speed and precision, resulting in minimal heat-affected zones and strong, precise welds.

- Deep penetration capabilities, enabling strong fusion and excellent joint strength.

- Minimal thermal distortion due to concentrated heat input, leading to strong, distortion-free welds.

Precision And Control In Welding

Tig Welding Precision

Tig welding offers precise control over the welding process.

Laser Welding Accuracy

Laser welding ensures high accuracy and precision in welding.

Speed And Efficiency Showdown

Tig Welding Speed

Tig welding is known for its precision and control.

It requires skilled operators to achieve optimal speed.

Laser Welding Efficiency

Laser welding operates at high speed and efficiency.

It can be automated for consistent and fast results.

Cost Implications And Investment

Tig welding and laser welding are two popular methods for joining metals, each with its own set of advantages and cost implications. When considering the cost implications and investment for these welding processes, it’s important to evaluate both the initial investment and operational costs associated with each method.

Initial Investment

Tig Welding: The initial investment for Tig welding equipment includes the cost of the welding machine, shielding gas, filler material, and other accessories. Specialized training may be required for welders to effectively operate Tig welding equipment, adding to the initial investment.

Laser Welding: In contrast, laser welding typically requires a higher initial investment due to the cost of the laser welding machine, optical systems, and safety measures. However, laser welding equipment often offers higher precision and automation, which can contribute to long-term cost savings.

Operational Costs

Tig Welding: Operational costs for Tig welding primarily include the expenses for electricity, shielding gas, and consumable materials such as tungsten electrodes and filler metal. Additionally, labor costs for skilled welders play a significant role in the overall operational expenses.

Laser Welding: Laser welding operational costs involve electricity, maintenance of the laser equipment, and periodic replacement of optical components. While labor costs may be lower due to increased automation, the maintenance and service costs for laser welding equipment should be considered.

Safety Considerations In Welding

When it comes to welding, safety considerations are paramount. Whether you’re engaging in TIG (Tungsten Inert Gas) welding or laser welding, it’s crucial to adhere to stringent safety measures and protocols to protect yourself and others from potential hazards.

Tig Welding Safety Measures

TIG welding, also known as GTAW (Gas Tungsten Arc Welding), requires specific safety measures to mitigate the risks associated with the process. Operators must wear protective gear, including a welding helmet with a proper shade, flame-resistant clothing, gloves, and closed-toe shoes. Adequate ventilation is essential to prevent exposure to harmful fumes and gases produced during the welding process.

- Wear a welding helmet with a proper shade

- Use flame-resistant clothing, gloves, and closed-toe shoes

- Ensure adequate ventilation

Laser Welding Safety Protocols

Laser welding, on the other hand, necessitates adherence to distinct safety protocols due to the use of high-powered laser beams. Protective eyewear designed to filter specific wavelengths of light is imperative to shield the eyes from potential damage. Furthermore, the workspace must be equipped with safety interlocks and barriers to prevent accidental exposure to the laser beam.

Proper training and certification for handling laser welding equipment are crucial to ensure safe and efficient operation.

- Wear protective eyewear designed to filter specific wavelengths of light

- Implement safety interlocks and barriers in the workspace

- Receive proper training and certification for handling laser welding equipment

Environmental Impact

Comparing Tig welding and laser welding, Tig welding has a higher environmental impact due to the use of shielding gases and filler materials. Laser welding, on the other hand, is more eco-friendly as it generates less waste and consumes less energy.

Tig Welding Environmental Concerns

Tig welding is a conventional welding process that uses a tungsten electrode to produce an arc for welding. Although Tig welding is a popular welding technique, it has some environmental concerns. Tig welding produces a significant amount of heat, which can contribute to climate change.

The heat produced by Tig welding can also cause air pollution, which can harm the environment and human health. Tig welding requires a lot of energy, and the energy comes from non-renewable sources, which are harmful to the environment.

Laser Welding Eco-friendliness

Compared to Tig welding, laser welding is a more eco-friendly welding technique. Laser welding uses a laser beam to heat and melt the metal, which results in less heat exposure and less energy consumption. Laser welding is more energy-efficient than Tig welding, and it does not produce harmful gases and pollutants.

The laser beam is more precise, and it reduces the chances of waste material, resulting in less environmental impact. In conclusion, laser welding is a more eco-friendly welding technique than Tig welding. Tig welding has environmental concerns such as air pollution, high energy consumption, and heat production.

On the other hand, laser welding is energy-efficient, precise, and does not produce harmful gases and pollutants. Therefore, laser welding is a better option for those who want to reduce their environmental impact while still achieving high-quality welds.

Future Of Welding Technologies

Innovations In Tig Welding

Tig welding is evolving with advancements in automation and precision.

- Enhanced control over heat input

- Improved welding speed and efficiency

- Integration with robotics for complex tasks

Advancements In Laser Welding

Laser welding is pushing boundaries with its speed and accuracy.

- Precise welds with minimal distortion

- High-speed welding for increased productivity

- Application in various industries like automotive and aerospace

Real-world Case Studies

Explore real-world case studies comparing Tig Welding and Laser Welding techniques. Discover the advantages and limitations of each method in various industrial applications. Gain insights into the best practices for achieving optimal results based on these practical examples.

Notable Tig Welding Projects

Laser Welding In Advanced Manufacturing

Real-world case studies showcase the practical applications of Tig welding versus Laser welding.

Notable Tig Welding Projects

Tig welding used in creating artistic sculptures with intricate designs.

Tig welding ensures precise welds in aerospace components for optimal performance.

Laser Welding In Advanced Manufacturing

Laser welding employed in the production of microelectronics with high precision.

Laser welding utilized in medical device manufacturing for clean, accurate welds.

Making The Choice: Which Welding Is Right For You?

Making the Choice: Which Welding is Right for You?

Project Requirements

Before making a decision on which welding method is the best fit for your project, it’s essential to consider the specific requirements of the job at hand. TIG welding and laser welding each have their own strengths and weaknesses, and understanding the project’s demands is crucial in making an informed choice.

Choosing The Optimal Method

When it comes to selecting the optimal welding method, it’s important to evaluate various factors such as material type, thickness, joint design, and production volume. Both TIG and laser welding offer distinct advantages, and choosing the right method involves carefully considering these factors to ensure the best results for your project.

Conclusion

To sum up, both Tig welding and laser welding have their advantages and limitations. The choice between the two methods ultimately depends on the specific needs of the project. Understanding the differences and applications of each technique is crucial for achieving optimal welding results in various industries.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.