Tig welding has long been associated with the use of a foot pedal to control the welding arc. Technological advancements are changing the game, offering welders an alternative approach to this traditional method. In this article, we explore the concept of tig welding without a foot pedal, and how it can bring efficiency and convenience to the welding process.

By eliminating the need for a foot pedal, welders can enjoy a hands-free experience, allowing for better control and precision. This innovative approach utilizes advanced machine settings and automation technology to regulate the arc current, ensuring consistent and high-quality welds. Whether you’re a professional welder or a DIY enthusiast, this technique opens up new possibilities for improved productivity and ease of use.

Photo by reddit

Through a comprehensive analysis of the benefits, challenges, and techniques involved, this article will provide valuable insights into tig welding without a foot pedal. Discover how this alternative method can enhance your welding experience and take your skills to the next level. Stay tuned as we unlock the secrets to this groundbreaking approach in the world of tig welding.

What is TIG welding?

Tig welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a tungsten electrode to produce an electric arc. This arc generates the heat necessary to melt the base material and form a weld joint. Unlike other welding techniques, tig welding does not require a consumable electrode, making it ideal for welding thin materials and achieving precise welds.

Tig welding has been performed using a foot pedal to control the welding current. The foot pedal allows the welder to vary the amperage by adjusting the pressure applied to the pedal. This control over the welding current is crucial for achieving the desired penetration and weld quality. However, relying on a foot pedal can be cumbersome and limit the welder’s mobility.

Advantages of TIG welding without a foot pedal

Tig welding without a foot pedal offers several advantages over the traditional method. One of the key benefits is the ability to have a hands-free welding experience. By eliminating the need to control the welding current manually, welders can focus on positioning the torch and manipulating the filler material, leading to better control and precision.

Another advantage of tig welding without a foot pedal is the increased efficiency and productivity it offers. With the automation technology and advanced machine settings available today, welders can set the desired amperage before starting the weld and maintain a consistent current throughout the process. This results in faster welding speeds and reduces the risk of inconsistencies or defects in the weld.

Tig welding without a foot pedal simplifies the welding setup and reduces the equipment required. Without the foot pedal, welders can achieve the desired current by adjusting the settings on the welding machine. This streamlines the process and eliminates the need for additional accessories, making it more convenient and cost-effective.

Equipment and setup for TIG welding without a foot pedal

To perform tig welding without a foot pedal, you will need a welding machine that offers advanced control options and automation features. Look for a machine that allows you to set the desired amperage and control the welding current without the need for a foot pedal. Some machines also offer programmable settings, allowing you to save and recall specific welding parameters for different applications.

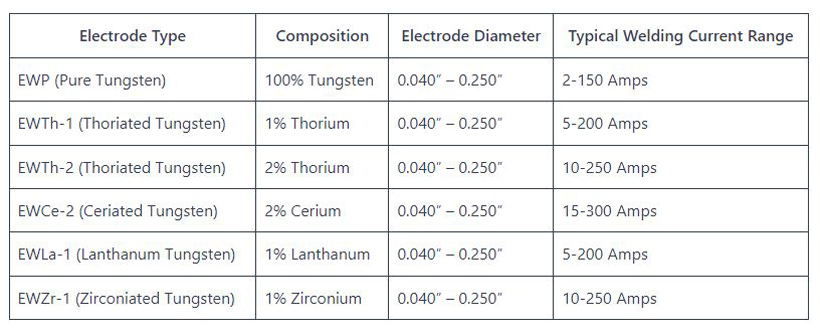

In addition to the welding machine, you will still need the standard tig welding equipment, including a tungsten electrode, shielding gas, filler material, and a welding torch. Ensure that your welding torch is compatible with the machine and has the necessary controls for regulating the gas flow and electrode positioning.

Before starting the weld, it’s important to properly set up the welding machine and adjust the settings to achieve the desired current. Refer to the machine’s user manual for instructions on how to navigate the control panel and make the necessary adjustments. Take the time to familiarize yourself with the machine’s features and ensure that everything is in working order before proceeding.

Techniques for controlling amperage without a foot pedal

Controlling the amperage without a foot pedal requires a different approach compared to traditional tig welding. Instead of manually adjusting the welding current during the weld, you will need to rely on the settings and automation features of the welding machine.

One technique is to pre-set the desired amperage before starting the weld. This involves adjusting the machine settings to the appropriate current based on the material thickness, joint configuration, and welding position. By setting the amperage in advance, you can maintain a consistent current throughout the weld, ensuring uniform penetration and weld quality.

Another technique is to take advantage of the pulse welding feature available in some welding machines. Pulse welding allows you to alternate between high and low currents during the weld, resulting in better heat control and reduced heat input into the base material. This can be particularly useful when welding thin or heat-sensitive materials.

Experiment with different techniques and settings to find the approach that works best for your specific welding requirements. It may take some practice and adjustment to achieve the desired weld results without the foot pedal, but with time, you can master the art of tig welding without this traditional control method.

Common challenges and solutions for TIG welding without a foot pedal

While tig welding without a foot pedal offers numerous benefits, it also presents some challenges that welders must overcome. One of the main challenges is adjusting to the new method of controlling the welding current. Without a foot pedal, welders need to rely on the machine settings and automation features to achieve the desired amperage.

To overcome this challenge, it’s important to thoroughly understand the capabilities and limitations of your welding machine. Familiarize yourself with the control panel and learn how to navigate the settings to adjust the amperage accurately. Take the time to experiment with different settings and techniques to find the optimal configuration for your welding needs.

Another common challenge is maintaining consistent weld quality without the foot pedal. With the foot pedal, welders have the flexibility to adjust the amperage on the fly, making it easier to compensate for variations in the welding conditions. Without this control, it’s crucial to pay close attention to other factors that can affect the weld quality, such as travel speed, torch angle, and filler material manipulation.

To ensure consistent weld quality, practice good welding techniques and focus on maintaining a steady torch movement and travel speed. Take the time to prepare the joint properly, removing any contaminants or oxide layers that can affect the weld. Consider using a welding positioner or fixture to hold the workpiece in a stable position, allowing for smoother and more controlled welding.

Safety considerations for TIG welding without a foot pedal

When performing tig welding without a foot pedal, it’s important to prioritize safety to protect yourself and others in the work environment. Follow these safety considerations to minimize the risk of accidents and injuries:

- Always wear appropriate personal protective equipment (PPE), including welding gloves, a welding helmet with a proper shade of lens, and flame-resistant clothing.

- Ensure proper ventilation in the welding area to prevent the accumulation of harmful fumes and gases. Use a fume extraction system or work in a well-ventilated space.

- Be mindful of the electrical hazards associated with welding. Inspect the welding machine and cables regularly for any signs of damage or wear. Avoid touching the electrode or workpiece while the machine is operating.

- Keep a fire extinguisher nearby and familiarize yourself with its proper use. In the event of a fire, act quickly and follow the appropriate steps to extinguish the flames safely.

- Maintain a clean and organized work area. Remove any flammable materials or debris that can pose a fire hazard. Keep your workspace free from clutter to minimize the risk of accidents.

By following these safety considerations, you can ensure a safe and secure tig welding experience without a foot pedal.

Tips for improving weld quality without a foot pedal

To achieve high-quality welds without a foot pedal, consider implementing the following tips:

- Practice proper torch manipulation techniques to maintain a consistent arc length. Keep the torch at the correct angle and distance from the workpiece to achieve optimal heat input and penetration.

- Pay attention to the filler material and ensure proper manipulation to create a uniform and aesthetically pleasing weld. Experiment with different hand movements and techniques to achieve the desired results.

- Invest in a high-quality welding machine with advanced control options and automation features. A reliable machine can make a significant difference in weld quality and overall welding experience.

- Take advantage of available welding accessories, such as a remote control device or a foot switch, if you still prefer to have some level of manual control over the welding current.

- Continuously improve your welding skills through practice and training. Attend welding workshops or courses to learn new techniques and stay up-to-date with the latest advancements in tig welding.

By implementing these tips, you can enhance your weld quality and overcome the challenges of tig welding without a foot pedal.

Comparison of TIG welding with and without a foot pedal

When comparing tig welding with and without a foot pedal, it’s essential to consider the advantages and limitations of each method. The traditional tig welding process with a foot pedal offers the flexibility to adjust the welding current on the fly, making it easier to adapt to changing welding conditions. This method can be cumbersome and limit the welder’s mobility.

On the other hand, tig welding without a foot pedal brings efficiency and convenience to the welding process. By relying on advanced machine settings and automation technology, welders can achieve a hands-free experience and maintain a consistent welding current. This method streamlines the welding setup and reduces the equipment required, making it more user-friendly and cost-effective.

The choice between tig welding with or without a foot pedal depends on individual preferences, welding requirements, and the availability of suitable equipment. Both methods have their merits, and welders should consider their specific needs and goals when deciding which approach to adopt.

Conclusion

Tig welding without a foot pedal is a game-changer in the world of welding. By utilizing advanced machine settings and automation technology, welders can enjoy a hands-free welding experience, resulting in improved control, productivity, and ease of use. This alternative method opens up new possibilities for welders of all levels, from professionals to DIY enthusiasts.

Through this comprehensive analysis, we have explored the benefits, challenges, techniques, and safety considerations involved in tig welding without a foot pedal.

By following the tips and recommendations provided, you can enhance your welding skills and achieve high-quality welds using this innovative approach.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.