Soldering is a critical process when it comes to working with copper pipes. Understanding the different types of solder available in the market is essential for achieving a successful and long-lasting connection. The two main types of solder commonly used for copper pipe soldering are lead-free solder and lead-based solder.

Lead-free solder has gained popularity due to its environmentally friendly composition, making it a safer choice for both consumers and the planet.

Lead-based solder, on the other hand, has been a traditional go-to option known for its strong bond and durability. While lead-based solder is effective, it is important to consider the potential health risks associated with lead exposure. As regulations on lead content become stricter, many professionals are shifting towards lead-free alternatives for their soldering projects.

Image by reddit

When deciding between lead-free and lead-based solder, it is crucial to assess the specific requirements of your project. Factors such as the application, pipe diameter, and desired joint strength play a significant role in determining the most suitable solder for your copper pipe soldering needs.

Choosing the Right Solder for Copper Pipe

Selecting the right solder for your copper pipe project involves considering various factors to ensure a secure and leak-free connection. Lead-free solder is recommended for applications where environmental sustainability and safety are top priorities. Its composition, typically consisting of tin, copper, and silver, offers a reliable bond without the use of harmful lead.

On the other hand, lead-based solder continues to be a popular choice in situations where a high-strength joint is necessary. The addition of lead in the solder mixture enhances its bonding capabilities, making it ideal for demanding applications that require long-term reliability. However, it is essential to handle lead-based solder with caution and adhere to safety guidelines to minimize exposure risks.

When choosing the right solder for copper pipe soldering, it is advisable to consult industry standards and regulations to ensure compliance with safety and quality requirements. Additionally, seeking recommendations from experienced professionals can provide valuable insights into the most suitable solder for your specific project needs.

Flux and Its Importance in Soldering

Flux plays a crucial role in the soldering process by facilitating the flow of solder and promoting adhesion between the solder and the copper pipe. It acts as a cleaning agent, removing oxides and contaminants from the metal surfaces to create a clean bonding surface. Using flux is essential for achieving a strong and reliable joint when soldering copper pipes.

There are different types of flux available, such as rosin flux and acid flux, each designed for specific applications. Rosin flux is commonly used for electrical soldering due to its non-corrosive properties, making it suitable for delicate electronic components. Acid flux, on the other hand, is more aggressive and is typically used in plumbing applications to clean and prepare metal surfaces before soldering.

Applying the right type of flux in the correct amount is crucial for successful soldering. Excessive flux can cause soldering defects, while insufficient flux may result in poor adhesion and weak joints. By understanding the role of flux and selecting the appropriate type for your soldering project, you can ensure a professional finish and long-lasting connection.

Image by kurso

Preparing the Copper Pipe for Soldering

Proper preparation of the copper pipe is essential to ensure a successful soldering process and a secure joint. Before soldering, it is crucial to clean the pipe thoroughly to remove any dirt, grease, or oxidation that may hinder the bonding of the solder. Using a fine-grit sandpaper or emery cloth, gently scrub the exterior of the pipe to create a clean and rough surface for optimal adhesion.

After cleaning, applying flux to the cleaned area of the pipe is necessary to facilitate the soldering process. The flux helps prevent oxidation during heating and promotes the flow of solder, ensuring a strong and leak-free joint. It is important to evenly coat the soldering area with flux to guarantee uniform coverage and reliable adhesion.

In addition to cleaning and flux application, ensuring that the pipe ends are properly aligned and fit snugly together is crucial for creating a watertight connection. Proper preparation of the copper pipe sets the foundation for a successful soldering process and enhances the overall quality and durability of the joint.

Step-by-Step Guide to Soldering Copper Pipe

Soldering copper pipes requires precision and attention to detail to achieve a secure and reliable connection. Follow these step-by-step instructions to master the art of soldering and create professional-grade joints that withstand the test of time.

Cut and Clean the Pipe

Begin by cutting the copper pipe to the desired length using a tube cutter. Ensure that the cut is straight and free of burrs. Use a deburring tool to remove any sharp edges and clean the inside of the pipe.

Apply Flux

Apply a thin, even layer of flux to the outside of the pipe and the inside of the fitting using a flux brush. Make sure to coat the surfaces evenly to promote solder adhesion and prevent oxidation during heating.

Assemble the Joint

Insert the pipe into the fitting, ensuring a snug and secure fit. Wipe off any excess flux that may have squeezed out during assembly to prevent contamination of the solder joint.

Heat the Joint

Use a propane torch to heat the joint evenly, moving the flame back and forth to distribute heat. Once the fitting reaches the required temperature, touch the solder to the joint, allowing it to melt and flow into the connection through capillary action.

Cool and Clean

Allow the soldered joint to cool naturally without disturbing it. Once cooled, wipe off any flux residue using a damp cloth to reveal a clean and shiny joint.

Following these steps diligently and practicing proper soldering techniques will help you achieve professional results and create durable connections that meet industry standards.

Image by manmadediy

Some Mistakes to Avoid When Soldering Copper Pipe

While soldering copper pipes is a straightforward process, there are common mistakes that can compromise the integrity of the joint and result in leaks or weak connections. By being aware of these pitfalls and taking preventive measures, you can ensure a successful soldering experience and achieve reliable results.

Insufficient Cleaning

Failing to clean the pipe thoroughly before soldering can prevent proper adhesion of the solder, leading to weak joints and potential leaks. Ensure that the pipe surfaces are free of dirt, grease, and oxidation to promote optimal bonding.

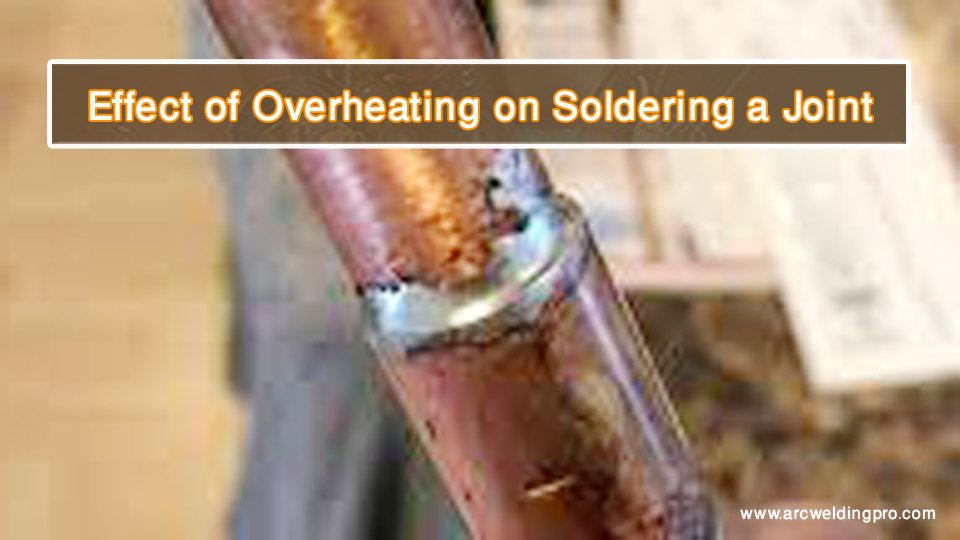

Overheating

Applying excessive heat to the joint can not only damage the pipe and fittings but also cause the solder to flow unevenly and create weak spots. Maintain a consistent heat level and avoid prolonged heating to prevent overheating and potential joint failure.

Poor Flux Application

Inadequate or uneven application of flux can hinder the flow of solder and result in incomplete coverage, leading to weak joints. Apply flux generously and evenly to ensure proper cleaning and solder adhesion.

Incorrect Pipe Alignment

Improper alignment of the pipe ends can cause misalignment of the joint, resulting in leaks and structural weakness. Ensure that the pipe ends fit together snugly and securely before soldering to create a watertight connection.

By avoiding these common mistakes and following best practices for soldering copper pipes, you can achieve reliable and durable joints that withstand the test of time and meet industry standards for quality and performance.

Safety Precautions When Soldering Copper Pipe

Soldering copper pipes involves working with high temperatures and potentially hazardous materials, making safety precautions a crucial aspect of the soldering process. By following essential safety guidelines, you can protect yourself from injury and ensure a safe working environment during soldering projects.

Ventilation

Always work in a well-ventilated area to prevent the buildup of fumes from soldering flux and materials. Proper ventilation helps dissipate harmful vapors and reduces the risk of inhalation exposure.

Protective Gear

Wear appropriate personal protective equipment, such as heat-resistant gloves, safety goggles, and long sleeves, to shield yourself from heat, sparks, and splatters during soldering. Protecting your skin and eyes is essential for preventing burns and injuries.

Fire Safety

Keep a fire extinguisher or a bucket of water nearby to extinguish any potential fires caused by accidental sparks or overheating during soldering. Be vigilant and prepared to respond quickly to emergencies to prevent accidents.

Heat Management

Exercise caution when working with open flames or hot soldering irons to avoid burns and heat-related injuries. Keep flammable materials away from the soldering area and handle hot tools with care to prevent accidents.

Prioritizing safety measures and creating a safe soldering environment are essential for preventing accidents and ensuring a smooth and successful soldering process. By following safety protocols and remaining vigilant throughout the soldering project, you can complete your work efficiently and without compromising personal wellbeing.

Image by kunkune

Selecting the Appropriate Solder for Copper Pipe

Choosing the right solder for your copper pipe soldering project is a critical decision that impacts the quality, durability, and safety of the final connection. Whether you opt for lead-free solder for its environmental benefits or prefer the strength of lead-based solder, understanding the differences and applications of each type is essential for achieving professional results.

By considering factors such as flux application, pipe preparation, and safety precautions, you can enhance the quality of your soldered joints and ensure leak-free connections that meet industry standards. Following best practices, avoiding common mistakes, and prioritizing safety measures are key elements in mastering the art of soldering copper pipes and creating reliable connections that stand the test of time.

Conclusion

Selecting the appropriate solder for your copper pipe project requires careful consideration of the specific requirements and desired outcomes. By leveraging the information and insights provided in this article, you can confidently choose the right solder and master the art of soldering copper pipes with precision and expertise.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.