Welding is an essential process in various industries, from construction to manufacturing. Single-phase welding machines are popular for their versatility and suitability for smaller workshops and home use. Understanding the wattage requirements of these machines is crucial for proper operation, safety, and energy management.

We’ll explore the power consumption of single-phase welding machines, factors affecting their wattage, and how to calculate and manage their power needs.

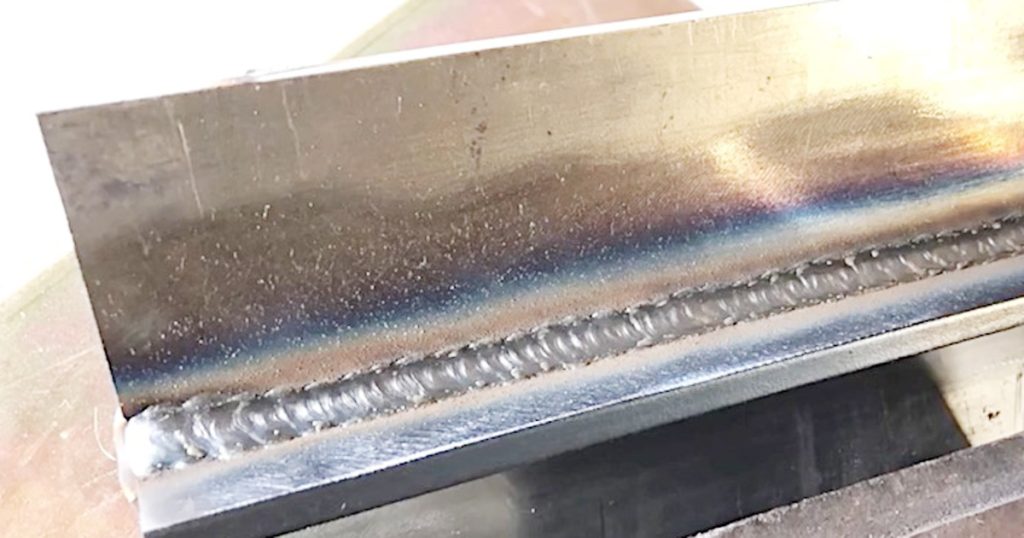

Image by amazon

Understanding Single-Phase Welding Machines

Single-phase welding machines are designed to operate on standard household electrical systems, typically running on 120V or 240V power supplies. These machines are commonly used for lighter welding tasks and are popular among hobbyists, small workshops, and for on-site repairs due to their portability and ease of use.

Calculating Wattage for Single-Phase Welding Machines

The wattage of a welding machine is a measure of its power consumption. To understand the wattage requirements, we need to consider the basic electrical formula:

Power (Watts) = Voltage (Volts) x Current (Amperes)

For single-phase welding machines, the voltage is typically either 120V or 240V, depending on the model and the power outlet available. The current (amperage) can vary based on the machine’s specifications and the welding process being used.

Let’s look at some examples:

- For a 120V welding machine: If the machine draws 15 amps, the wattage would be: 120V x 15A = 1,800 watts or 1.8 kW

- For a 240V welding machine: If the machine draws 30 amps, the wattage would be: 240V x 30A = 7,200 watts or 7.2 kW

It’s important to note that these calculations represent the continuous or running watts. Welding machines often require higher power during startup or for brief periods during operation.

Starting Wattage vs. Running Wattage

Welding machines, like many electrical devices, require more power to start up than they do to run continuously. This initial surge of power is known as the starting or peak wattage. While not always listed on spec sheets, a good rule of thumb is to add about 30% to the running wattage to estimate the starting wattage.

For example, using our 240V welding machine that draws 7,200 watts: Starting Wattage = 7,200W x 1.3 = 9,360 watts

This means that while the machine may run at 7,200 watts, it could require up to 9,360 watts during startup or peak operation.

Factors Affecting Wattage in Single-Phase Welding Machines

Several factors can influence the wattage requirements and consumption of single-phase welding machines:

Type of Welding Process

Different welding processes have varying power needs. For instance, TIG (Tungsten Inert Gas) welding typically requires less energy than MIG (Metal Inert Gas) welding. Stick welding often demands more power due to its higher current requirements.

Material Thickness

Welding thicker materials requires more power. As the thickness of the metal increases, so does the energy needed to heat and fuse it properly.

Duty Cycle Rating

The duty cycle of a welding machine indicates how long it can operate continuously within a 10-minute period before needing to cool down. Machines with higher duty cycles can sustain longer periods of high-power output, which may result in higher overall wattage consumption.

Machine Efficiency

Modern welding machines often incorporate more efficient transformers and power management systems, which can reduce overall power consumption while maintaining performance.

Welding Settings

The specific amperage and voltage settings used during welding will directly impact power consumption. Higher settings for more demanding jobs will increase wattage requirements.

Image by amazon

Managing Power Supply for Single-Phase Welding Machines

Proper power management is crucial when using single-phase welding machines:

Circuit Capacity

Ensure that your electrical circuit can handle the power requirements of your welding machine. Most household circuits are rated for 15 or 20 amps, which may not be sufficient for larger welding machines.

Dedicated Circuit

For larger single-phase welding machines, especially those operating at 240V, a dedicated circuit is often necessary to prevent overloading and ensure consistent power supply.

Generator Use

When using a generator to power a welding machine, make sure it can provide both the running and starting wattage required. For example, the EcoFlow DELTA Pro portable power station, with 3600W of continuous output and 7200W for startup, could handle many single-phase welding machines operating at 120V.

Voltage Drop

Be aware of voltage drop, especially when using long extension cords. Voltage drop can reduce the power available to your welding machine, affecting performance and potentially damaging the equipment.

Power Factor

Welding machines often have a power factor less than 1, which means they draw more apparent power than they convert to useful work. This can affect the actual power consumption and should be considered when sizing power supplies.

Image by indiamart

Safety Considerations

When dealing with the high power requirements of welding machines, safety is paramount:

- Always follow the manufacturer’s guidelines for power requirements and circuit specifications.

- Use properly rated extension cords and plugs designed for welding machines.

- Regularly inspect power cords and connections for signs of wear or damage.

- Install proper grounding for your welding machine to prevent electrical hazards.

- Consider using a surge protector or power conditioner to protect your welding machine from power fluctuations.

Improving Energy Efficiency

To optimize the power consumption of your single-phase welding machine:

- Choose the right machine for your needs. Oversized machines may consume unnecessary power.

- Maintain your welding machine regularly to ensure it operates at peak efficiency.

- Use the appropriate welding settings for each job to avoid excessive power consumption.

- Consider investing in newer, more energy-efficient welding machines if you’re using older models.

- Plan your welding tasks to minimize idle time and maximize productive use of power.

Conclusion

Understanding the wattage requirements of single-phase welding machines is essential for proper operation, safety, and energy management. By considering factors such as the type of welding process, material thickness, and machine specifications, you can accurately determine the power needs of your welding setup.

Remember that wattage calculations should account for both running and starting power requirements. Proper power management, including dedicated circuits and appropriate generators when necessary, ensures safe and efficient operation of your welding machine.

As welding technology continues to advance, manufacturers are developing more energy-efficient models that can deliver high performance with lower power consumption. When selecting a single-phase welding machine, consider both your immediate welding needs and long-term energy efficiency to make an informed choice.

By understanding and managing the wattage of your single-phase welding machine, you can ensure optimal performance, maintain safety, and potentially reduce energy costs in your welding projects.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.