Are you wondering if it’s possible to weld stainless steel to mild steel using flux core wire? Many welders are curious about this technique and whether it produces strong and reliable welds. We will explore the feasibility of welding stainless steel and mild steel together using flux core wire.

Differences between stainless steel and mild steel

Before we dive into the topic of welding stainless steel to mild steel, it’s important to understand the differences between these two materials. Stainless steel is known for its corrosion resistance and high strength, making it ideal for a wide range of applications. Mild steel, on the other hand, is more affordable and easier to work with, but it lacks the same level of corrosion resistance.

The composition of stainless steel includes chromium, which provides the material with its corrosion-resistant properties. Mild steel, on the other hand, is primarily made up of iron with a lower carbon content. These differences in composition and properties can make it challenging to weld stainless steel to mild steel.

Welding stainless steel to mild steel: challenges and considerations

Welding stainless steel to mild steel presents several challenges that need to be taken into consideration. One of the main challenges is the difference in melting points between these two materials. Stainless steel has a higher melting point compared to mild steel, which means that the welding process requires careful control of heat.

Another challenge is the risk of intermetallic corrosion, which occurs when dissimilar metals come into contact and react with each other. This can lead to weakened welds and reduced overall strength. It’s important to take preventative measures to minimize the risk of intermetallic corrosion when welding stainless steel to mild steel.

The difference in thermal conductivity between stainless steel and mild steel can affect the welding process. Stainless steel has a lower thermal conductivity compared to mild steel, which means that heat can build up more quickly in stainless steel. This requires adjustments to the welding parameters to ensure proper fusion and prevent overheating.

Flux core wire: what is it and how does it work?

To understand the feasibility of welding stainless steel to mild steel using flux core wire, let’s first take a closer look at what flux core wire is and how it works. Flux core wire is a type of welding electrode that contains a flux compound in its core. This flux compound releases gases when heated, which create a protective shield around the weld pool.

The flux core wire is designed to provide a few key benefits. First, it helps to protect the weld from atmospheric contamination, such as oxygen and nitrogen, which can weaken the welds. Second, it acts as a deoxidizer, removing impurities from the weld pool and enhancing the quality of the weld. Lastly, the flux core wire can provide additional alloying elements to improve the strength and corrosion resistance of the weld.

Can you use flux core wire to weld stainless steel to mild steel?

Now that we have a basic understanding of flux core wire, let’s address the main question: can you use flux core wire to weld stainless steel to mild steel? The answer is yes, it is possible to use flux core wire for this type of welding. There are some limitations and considerations to keep in mind.

One of the main limitations is that not all flux core wires are suitable for welding stainless steel to mild steel. Some flux core wires are specifically designed for welding mild steel and may not provide the necessary alloying elements for stainless steel. It’s important to choose a flux core wire that is specifically formulated for stainless steel to ensure optimal results.

Welding stainless steel to mild steel with flux core wire may require adjustments to the welding parameters. The higher melting point and lower thermal conductivity of stainless steel may require higher heat input and slower travel speeds compared to welding mild steel. It’s important to experiment with different settings and techniques to find the optimal parameters for this type of welding.

Pros and cons of using flux core wire for stainless steel to mild steel welding

Using flux core wire for welding stainless steel to mild steel offers several advantages and disadvantages. Let’s take a closer look at the pros and cons of this welding technique.

Pros of using flux core wire:

Increased convenience

Flux core wire eliminates the need for an external shielding gas, making it more convenient and portable compared to gas metal arc welding (GMAW).

Cost-effective

Flux core wire is generally more affordable than solid wire with gas shielding, making it a cost-effective option for certain applications.

Enhanced corrosion resistance

The flux compound in the core of the wire can provide additional alloying elements, improving the corrosion resistance of the weld.

Cons of using flux core wire:

Limited position capabilities

Flux core wire is better suited for flat and horizontal welding positions, as it can be more challenging to achieve proper fusion in vertical and overhead positions.

Increased spatter

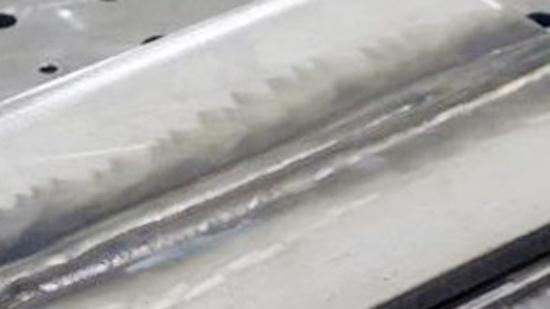

Flux core wire tends to produce more spatter compared to solid wire with gas shielding, which can result in a messier weld and require additional post-weld cleaning.

Limited alloying options

While there are flux core wires available for welding stainless steel to mild steel, the range of alloying options may be more limited compared to solid wire with gas shielding.

Alternative methods for welding stainless steel to mild steel

If using flux core wire is not the ideal solution for your welding needs, there are alternative methods available for welding stainless steel to mild steel. Here are a few options worth considering:

Gas metal arc welding (GMAW)

Also known as MIG welding, GMAW uses a solid wire electrode and an external shielding gas to protect the weld pool. This method offers more control and versatility compared to flux core wire welding but requires a separate gas supply.

Tungsten inert gas (TIG) welding

TIG welding is a precise and versatile method that uses a non-consumable tungsten electrode and an external shielding gas. This method is well-suited for welding stainless steel to mild steel but requires a higher skill level and more complex equipment.

Stick welding

Stick welding, also known as shielded metal arc welding (SMAW), uses a consumable electrode coated in flux to create a protective shield around the weld pool. While stick welding can be used for welding stainless steel to mild steel, it may not provide the same level of control and quality as other methods.

Welding stainless steel to mild steel: best practices and tips

Regardless of the welding method you choose, there are some best practices and tips that can help ensure successful welds when joining stainless steel to mild steel. Here are some recommendations to keep in mind:

Cleanliness is key

Thoroughly clean the surfaces to be welded, removing any dirt, oil, or contaminants that can affect the quality of the weld. Use a stainless steel brush or solvent to clean stainless steel surfaces and a wire brush for mild steel.

Preheat when necessary

Depending on the thickness of the materials and the welding method used, preheating may be required to prevent excessive heat buildup and improve fusion. Consult the welding procedure specifications (WPS) for specific preheating recommendations.

Use proper fit-up and joint design

Ensure that the joint fit-up is tight and properly aligned to achieve good fusion. Consider using a bevel or V-groove joint design for improved strength and penetration.

Adjust the welding parameters

Experiment with different settings and techniques to find the optimal welding parameters for stainless steel to mild steel welding. Adjustments may be necessary to account for the differences in melting points and thermal conductivity between the two materials.

Practice proper technique

Maintain a steady hand and a consistent travel speed to ensure even heat distribution and proper fusion. Avoid excessive weaving or oscillation, as this can lead to inconsistent welds.

Post-weld treatment

After welding, it’s important to properly treat the weld to minimize the risk of intermetallic corrosion. This can include applying a passivation treatment or using a corrosion-resistant coating.

Some mistakes to avoid when welding stainless steel to mild steel

When attempting to weld stainless steel to mild steel, there are some common mistakes that should be avoided to ensure the best results. Here are a few of the most common pitfalls to watch out for:

Neglecting proper surface preparation

Failing to thoroughly clean and prepare the surfaces before welding can result in poor fusion and weak welds. Take the time to properly clean and prepare the materials to achieve the best results.

Using the wrong flux core wire

Not all flux core wires are suitable for welding stainless steel to mild steel. Using the wrong wire can result in weak and brittle welds. Be sure to choose a flux core wire specifically formulated for stainless steel.

Overheating the stainless steel

Stainless steel has a lower thermal conductivity compared to mild steel, which means it can heat up more quickly. Overheating the stainless steel can result in excessive distortion and weak welds. Adjust the welding parameters accordingly to prevent overheating.

Neglecting intermetallic corrosion prevention

The risk of intermetallic corrosion is a significant concern when welding stainless steel to mild steel. Failing to take preventative measures, such as using proper shielding gas or applying a corrosion-resistant treatment, can result in weakened welds.

Conclusion

Welding stainless steel to mild steel using flux core wire is indeed possible, but it requires careful consideration and proper technique. Flux core wire offers convenience and cost-effectiveness, but it may have limitations in terms of position capabilities and alloying options. Alternative methods such as GMAW and TIG welding can provide more control and versatility, but they may require additional equipment and expertise.

When choosing the right welding method for your project, consider the specific requirements and constraints you are working with. Evaluate factors such as material properties, joint design, position requirements, and the desired strength and corrosion resistance of the weld. Consulting with a welding professional or conducting thorough research can help you make an informed decision and achieve the best results.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.