Welding heat input is a critical parameter in the welding process that significantly influences the quality, strength, and properties of the resulting weld. Understanding and controlling heat input is essential for welders, engineers, and fabricators to produce high-quality welds that meet specific requirements.

In this guide, we’ll explore the concept of welding heat input, its calculation, effects on weld properties, and best practices for managing it effectively.

Image by thefabricator

What is Welding Heat Input?

Welding heat input is defined as the amount of energy transferred per unit length of weld. It is a measure of the thermal energy delivered to the base material during the welding process. Heat input is typically expressed in units of joules per millimeter (J/mm) or kilojoules per inch (kJ/in).

Importance of Heat Input

Heat input plays a crucial role in determining:

- Weld bead geometry

- Mechanical properties of the weld

- Microstructure of the weld and heat-affected zone (HAZ)

- Susceptibility to weld defects

- Residual stresses and distortion

Calculating Welding Heat Input

The most common equation used for calculating welding heat input is:

Heat Input = (Voltage ? Amperage ? 60) / (Travel Speed ? 1000)

Where:

- Heat Input is in kJ/in or J/mm

- Voltage is in volts (V)

- Amperage is in amperes (A)

- Travel Speed is in inches per minute (in/min) or millimeters per minute (mm/min)

Factors Affecting Heat Input

Voltage

Higher voltage increases arc length, which can lead to a wider weld bead and increased heat input.

Amperage

Higher amperage increases the amount of heat generated, directly affecting heat input.

Travel Speed

Slower travel speeds result in higher heat input, as more energy is deposited per unit length of weld.

Welding Process Efficiency

Different welding processes have varying efficiencies in transferring heat to the base material. For more accurate calculations, a process efficiency factor can be included:

Heat Input = (Voltage ? Amperage ? 60 ? Efficiency) / (Travel Speed ? 1000)

Typical efficiency factors:

- SMAW (Stick welding): 0.7-0.8

- GMAW (MIG welding): 0.7-0.8

- GTAW (TIG welding): 0.6-0.7

- SAW (Submerged Arc Welding): 0.9-0.99

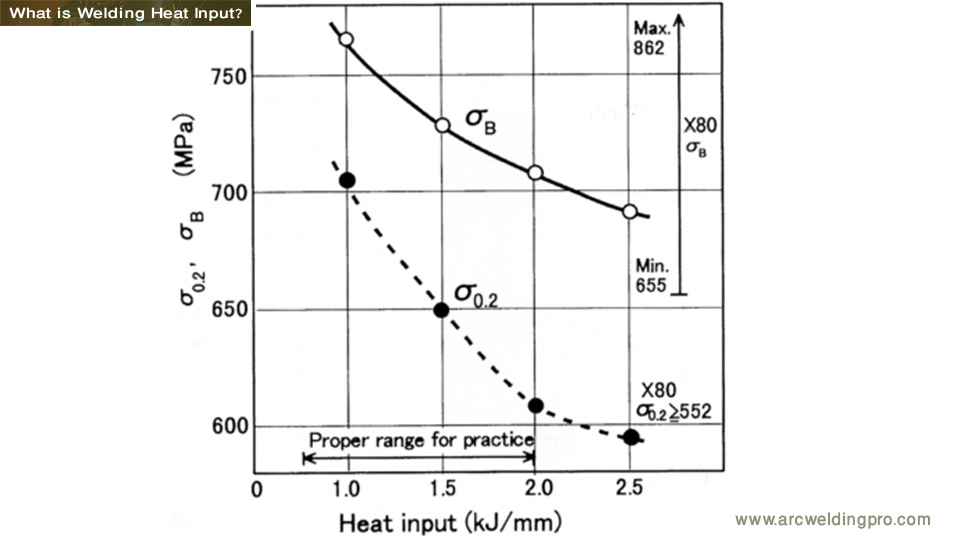

Image by kobelco-welding

Effects of Heat Input on Weld Properties

Mechanical Properties

Strength and Toughness

Higher heat input generally leads to slower cooling rates, which can result in: – Increased grain size in the weld and HAZ – Reduced strength and hardness – Potentially improved toughness in some materials

Lower heat input typically results in:

- Finer grain structure

- Increased strength and hardness

- Potentially reduced toughness in some materials

Ductility

Moderate heat input often provides the best balance of strength and ductility. Extremely high or low heat inputs can negatively impact ductility.

Microstructure

Heat input significantly influences the microstructure of the weld and HAZ:

- High heat input: Promotes the formation of coarse grains and may lead to undesirable phases in some materials.

- Low heat input: Results in finer grain structures but may lead to incomplete fusion or lack of penetration.

Residual Stresses and Distortion

Higher heat input generally leads to:

- Increased residual stresses

- Greater potential for distortion

- Larger HAZ

Lower heat input typically results in:

- Reduced residual stresses

- Less distortion

- Smaller HAZ

Susceptibility to Weld Defects

High Heat Input:

- May increase the risk of hot cracking in susceptible materials

- Can lead to excessive penetration or burn-through in thin materials

- May cause grain boundary liquation in some alloys

Low Heat Input:

- Can increase the risk of lack of fusion or incomplete penetration

- May lead to cold cracking in hardenable steels

- Can result in porosity due to rapid solidification

Image by hobartbrothers

Optimizing Heat Input for Different Materials

Carbon and Low-Alloy Steels

- Moderate heat input is generally preferred

- High heat input may reduce strength and toughness

- Low heat input may increase the risk of hydrogen-induced cracking in hardenable steels

Stainless Steels

- Lower heat input is often preferred to maintain corrosion resistance

- High heat input can lead to sensitization in austenitic stainless steels

- Duplex stainless steels require careful control of heat input to maintain proper phase balance

Aluminum Alloys

- Lower heat input is generally preferred due to high thermal conductivity

- High heat input can lead to excessive grain growth and reduced strength

- Very low heat input may result in lack of fusion or porosity

High-Strength Steels

- Careful control of heat input is critical

- Low heat input may be necessary to maintain strength and toughness

- Preheat and interpass temperature control are often required

Effects of High vs Low Heat Input

| Aspect | High Heat Input | Low Heat Input |

|---|---|---|

| Grain Size | Larger grains | Finer grains |

| Strength | Generally lower | Generally higher |

| Toughness | Variable (material dependent) | Variable (material dependent) |

| Residual Stress | Higher | Lower |

| Distortion | Greater | Less |

| HAZ Size | Larger | Smaller |

| Penetration | Deeper | Shallower |

| Cooling Rate | Slower | Faster |

| Risk of Hot Cracking | Higher | Lower |

| Risk of Cold Cracking | Lower | Higher (in hardenable steels) |

Best Practices for Managing Heat Input

Use Appropriate Welding Parameters

- Select voltage, amperage, and travel speed based on material thickness and welding position

- Follow welding procedure specifications (WPS) when available

Choose the Right Welding Process

- Consider using processes with higher deposition rates for thick materials

- Use low heat input processes for thin materials or heat-sensitive alloys

Implement Proper Heat Management Techniques

- Use preheat and interpass temperature control when required

- Apply post-weld heat treatment (PWHT) to relieve residual stresses when necessary

Optimize Joint Design

- Use narrow groove designs to reduce the volume of weld metal and overall heat input

- Consider using backing bars or ceramic backing to improve heat dissipation

Monitor and Control Heat Input

- Use welding data acquisition systems to monitor and record welding parameters

- Train welders on the importance of maintaining consistent travel speed

Employ Advanced Welding Techniques

- Consider pulsed welding processes to reduce overall heat input while maintaining penetration

- Explore the use of low heat input variants of traditional welding processes

Conclusion

Welding heat input is a critical parameter that significantly influences the quality and properties of welds. By understanding the factors that affect heat input and its impact on weld characteristics, welders and engineers can optimize their welding processes to achieve the desired results.

Proper management of heat input requires a balance between various factors, including material properties, joint design, welding process selection, and specific project requirements. By carefully controlling heat input, it’s possible to produce high-quality welds with optimal mechanical properties, minimal defects, and reduced residual stresses and distortion.

As welding technology continues to advance, new techniques and processes are being developed to provide even greater control over heat input. These innovations, combined with a solid understanding of heat input principles, will enable welders to tackle increasingly complex welding challenges and produce superior welds across a wide range of materials and applications.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.