Personal Protective Equipment (PPE) refers to a range of equipment designed to protect individuals from potential hazards in the workplace. This can include items such as helmets, gloves, safety glasses, high-visibility clothing, and respiratory protective equipment.

PPE is essential for ensuring the safety and well-being of workers in various industries, including construction, manufacturing, healthcare, and emergency services. By wearing the appropriate PPE, workers can reduce the risk of injuries and illnesses caused by exposure to physical, chemical, biological, or radiological hazards.

Image by facebook

Employers are responsible for providing and maintaining PPE, while employees have a duty to use the equipment correctly and report any defects or issues.

Personal Protective Equipment

Personal Protective Equipment (PPE) is essential in various industries to protect individuals from workplace hazards. Whether it’s construction, healthcare, or manufacturing, PPE plays a crucial role in ensuring the safety and well-being of workers.

Ppe In Safety

PPE serves as a shield against potential dangers, such as chemical exposure, physical impact, or airborne particles. By wearing the appropriate gear, individuals can minimize the risk of injuries and illnesses while on the job.

Historical Evolution Of Ppe

PPE has evolved over centuries, adapting to the changing needs and advancements in technology. From rudimentary forms of protection to sophisticated gear designed for specific hazards, the history of PPE showcases the continual efforts to enhance workplace safety.

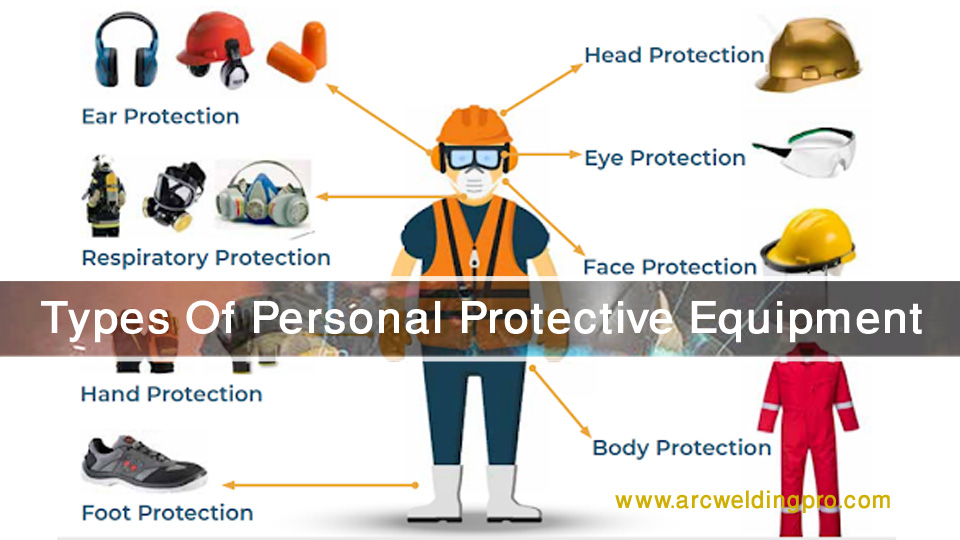

Types Of Personal Protective Equipment

When working in hazardous environments, it is crucial to prioritize safety by utilizing Personal Protective Equipment (PPE). PPE refers to equipment designed to protect individuals from serious injuries or illnesses resulting from contact with chemical, physical, electrical, mechanical, or other workplace hazards. There are various types of PPE, each serving a specific protective function.

Head And Face Protection

Head and face protection includes helmets, hard hats, and face shields. These are essential for safeguarding against falling objects, electrical hazards, and impacts to the head and face.

Eye And Hearing Protection

Eye protection includes safety glasses and goggles to shield the eyes from debris, chemicals, and intense light. Hearing protection involves earplugs and earmuffs to reduce exposure to loud noises and prevent hearing damage.

Respiratory Protective Devices

Respiratory protective devices such as respirators and masks are critical for filtering out harmful particles, gases, and vapors, ensuring safe breathing in contaminated or oxygen-deficient environments.

Protective Clothing

Protective clothing encompasses coveralls, gloves, aprons, and vests, serving as a barrier against chemical splashes, heat, flames, and other workplace hazards.

Hand And Foot Protection

Hand protection involves gloves tailored to specific tasks, such as cut-resistant gloves, chemical-resistant gloves, and insulated gloves. Foot protection includes safety shoes and boots designed to prevent injuries from punctures, slips, and electrical hazards.

Image by maxi-seal

Industry-specific Ppe Requirements

Different industries have specific requirements for Personal Protective Equipment (PPE). PPE includes gear like helmets, gloves, and goggles, tailored to protect workers in various sectors, from construction to healthcare. Adhering to industry-specific PPE guidelines is crucial to ensure the safety and well-being of employees.

Personal Protective Equipment (PPE) is a crucial aspect of workplace safety across various industries. However, different industries have different hazards and risks, which require specific types of PPE. In this section, we will discuss the industry-specific PPE requirements for the Healthcare sector, Construction Industry, Manufacturing and Engineering, and Chemical Handling.

Healthcare Sector

Healthcare workers are exposed to various hazards such as biological agents, radiation, and chemicals. Therefore, PPE requirements for the healthcare sector include gloves, gowns, masks, respirators, and eye protection. These PPE are used to protect healthcare workers from exposure to infectious diseases, radiation, and harmful chemicals.

Construction Industry

Construction workers are exposed to various hazards such as falling objects, noise, dust, and chemicals. Therefore, PPE requirements for the construction industry include hard hats, safety glasses, earplugs, respirators, and safety boots. These PPE are used to protect construction workers from head injuries, hearing loss, respiratory problems, and foot injuries.

Manufacturing And Engineering

Manufacturing and engineering workers are exposed to various hazards such as chemicals, noise, and machinery. Therefore, PPE requirements for the manufacturing and engineering industry include earplugs, safety glasses, respirators, hard hats, and safety shoes. These PPE are used to protect manufacturing and engineering workers from hearing loss, eye injuries, respiratory problems, and head injuries.

Chemical Handling

Chemical handling workers are exposed to various hazards such as chemical splashes, inhalation, and skin absorption. Therefore, PPE requirements for chemical handling include chemical-resistant gloves, goggles, respirators, and protective clothing. These PPE are used to protect chemical handling workers from chemical burns, respiratory problems, and skin absorption.

It is essential to understand industry-specific PPE requirements to ensure the safety of workers in different industries. Employers should provide appropriate PPE and ensure that workers receive proper training on how to use and maintain them.

Proper Use and Maintenance Of Ppe

When it comes to ensuring workplace safety, understanding the proper use and maintenance of Personal Protective Equipment (PPE) is crucial. By following guidelines for correct fit, usage, cleaning, storage, regular inspection, and replacement of PPE, individuals can effectively protect themselves from potential hazards. Let’s delve into the essential aspects of maintaining and using PPE to guarantee maximum protection.

Correct Fit And Usage

Proper fit is essential for PPE to effectively safeguard individuals. It is vital to choose the right size and ensure a secure fit to prevent exposure to hazards. Always follow the manufacturer’s guidelines for correct usage and adjust the equipment to fit snugly, without being too tight or too loose.

Cleaning And Storage

Regular cleaning and proper storage of PPE are critical to maintain its effectiveness and prolong its lifespan. It’s important to clean the equipment after each use using the recommended cleaning agents and methods. Store PPE in a clean, dry area away from direct sunlight, extreme temperatures, and chemicals to prevent damage.

Regular Inspection And Replacement

Regularly inspecting PPE for signs of wear, tear, or damage is crucial for ensuring its reliability. Replace any damaged or deteriorated equipment immediately to prevent compromised protection. Establish a schedule for routine inspections and replacements to guarantee the continuous effectiveness of PPE.

Image by shponline co

Challenges In Ppe Management

Managing Personal Protective Equipment (PPE) poses several challenges that organizations need to address effectively. These challenges revolve around Ensuring Compliance, Dealing with PPE Shortages, and Innovations in PPE Technology.

Ensuring Compliance

- Regular training sessions for employees on proper PPE usage.

- Implementing strict policies to enforce PPE guidelines.

- Regular audits to ensure adherence to safety protocols.

Dealing With Ppe Shortages

- Establishing effective inventory management systems.

- Seeking alternative suppliers to mitigate shortages.

- Implementing conservation strategies for critical PPE items.

Innovations In Ppe Technology

Organizations are leveraging technology to enhance PPE effectiveness:

| Technology | Benefits |

|---|---|

| Smart Sensors | Real-time monitoring of PPE usage and conditions. |

| Antimicrobial Fabrics | Reduced risk of contamination and extended usability. |

| Augmented Reality | Training simulations for complex PPE scenarios. |

Training and Education On Ppe

Proper training and education on Personal Protective Equipment (PPE) is crucial for ensuring the safety and well-being of individuals in various industries and work environments. By providing essential training programs, creating awareness, and emphasizing the roles of supervisors and safety officers, organizations can effectively promote the use of PPE and minimize the risk of workplace accidents and injuries.

Essential Training Programs

Implementing comprehensive training programs is essential to educate employees on the importance of using appropriate PPE and how to correctly wear and maintain it. These training sessions should cover various aspects, including:

- Identifying different types of PPE required for specific tasks or hazards

- Proper fitting and adjustment techniques for maximum effectiveness

- Understanding the limitations and lifespan of different PPE

- Recognizing signs of wear and tear and knowing when to replace equipment

- Proper storage and maintenance procedures to ensure longevity

Creating Awareness

Creating awareness about the importance of PPE is crucial in fostering a safety culture within the organization. This can be achieved through various means:

- Displaying informative posters and signage in prominent areas

- Conducting regular safety meetings and toolbox talks to reinforce the significance of PPE

- Incorporating PPE-related topics in safety newsletters or internal communications

- Encouraging open dialogue and feedback on PPE usage and concerns

Role Of Supervisors And Safety Officers

Supervisors and safety officers play a pivotal role in ensuring the effective implementation of PPE measures. They should:

- Lead by example and consistently wear appropriate PPE

- Regularly inspect work areas to identify any PPE deficiencies or non-compliance

- Provide guidance and feedback to employees on proper PPE usage

- Encourage a proactive approach to safety by addressing any concerns or issues promptly

- Maintain records of PPE training, inspections, and incidents for future reference

By emphasizing the importance of training and education on PPE, organizations can ensure that employees are equipped with the knowledge and skills needed to protect themselves and others in the workplace.

Legal and Regulatory Aspects Of Ppe

Personal Protective Equipment (PPE) refers to clothing, helmets, goggles, or other equipment designed to protect the wearer’s body from injury or infection. The legal and regulatory aspects of PPE include ensuring that the equipment meets safety standards, proper usage and maintenance, and providing adequate training to employees.

Personal Protective Equipment (PPE) is essential for protecting employees from workplace hazards. However, using PPE is not just a matter of safety, but also a legal obligation. Employers are required to provide PPE to their employees, and employees must wear and use it properly. Failure to comply with PPE regulations can lead to serious penalties and fines.

Osha Standards

The Occupational Safety and Health Administration (OSHA) is the primary regulatory agency responsible for ensuring workplace safety in the United States. OSHA has established standards for PPE to protect employees from various hazards, such as physical, chemical, biological, and radiological.

According to OSHA, employers are responsible for assessing workplace hazards and selecting appropriate PPE for their employees. Employers are also responsible for providing training to their employees on how to use and maintain PPE.

International Safety Regulations

In addition to OSHA, there are several international safety organizations that establish PPE regulations. These organizations include the International Organization for Standardization (ISO), the European Union (EU), and the International Labour Organization (ILO). These organizations provide guidelines and standards for PPE that are used worldwide. Employers must comply with these regulations when operating in countries outside of the United States.

Rights and Responsibilities Of Employers And Employees

Both employers and employees have specific rights and responsibilities when it comes to PPE. Employers are responsible for providing PPE, maintaining and replacing PPE when necessary, and ensuring that PPE is used properly. Employees, on the other hand, are responsible for wearing and using PPE properly, reporting any defects or problems with PPE to their employer, and attending training sessions on PPE. It is essential for both employers and employees to understand their roles and responsibilities when it comes to PPE to ensure a safe and healthy workplace.

PPE is not only essential for employee safety but also a legal obligation for employers. It is essential for employers to comply with OSHA standards and international safety regulations and for both employers and employees to understand their rights and responsibilities regarding PPE. By following these regulations and guidelines, we can ensure a safe and healthy work environment for everyone.

Future Of Personal Protective Equipment

Smart Ppe

Incorporating advanced technology, Smart PPE is revolutionizing safety gear. Equipped with sensors and connectivity, it provides real-time monitoring of environmental conditions and the wearer’s vital signs, enhancing safety and productivity.

Sustainable And Eco-friendly Options

The future of PPE is embracing sustainability with the development of eco-friendly materials and recyclable designs. Sustainable options reduce environmental impact while ensuring worker safety, reflecting a growing emphasis on corporate social responsibility.

Advancements In Material Science

Breakthroughs in material science are leading to the creation of lighter, more durable, and ergonomically designed PPE. These advancements are improving comfort and mobility while maintaining the highest levels of protection.

Conclusion

Personal Protective Equipment (PPE) is crucial for safety in various industries. By understanding the types and proper usage, workers can ensure their well-being. Employers must provide adequate PPE and workers must wear it correctly to prevent accidents and injuries. Stay informed and prioritize safety in the workplace.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.