Hot pressure welding is a specialized welding process that uses a combination of heat and pressure to join two or more materials, typically metals. Unlike traditional fusion welding, which primarily relies on melting the materials at the joint, hot pressure welding utilizes the application of heat to soften the materials and pressure to force them together. This process results in a bond that is strong, reliable, and often more uniform than other types of welding.

Hot pressure welding is commonly used in industries where precise and robust joints are needed, such as in aerospace, automotive manufacturing, and electrical engineering. The process is particularly advantageous for joining dissimilar metals or creating welds that must withstand high levels of stress and pressure in their operational environments.

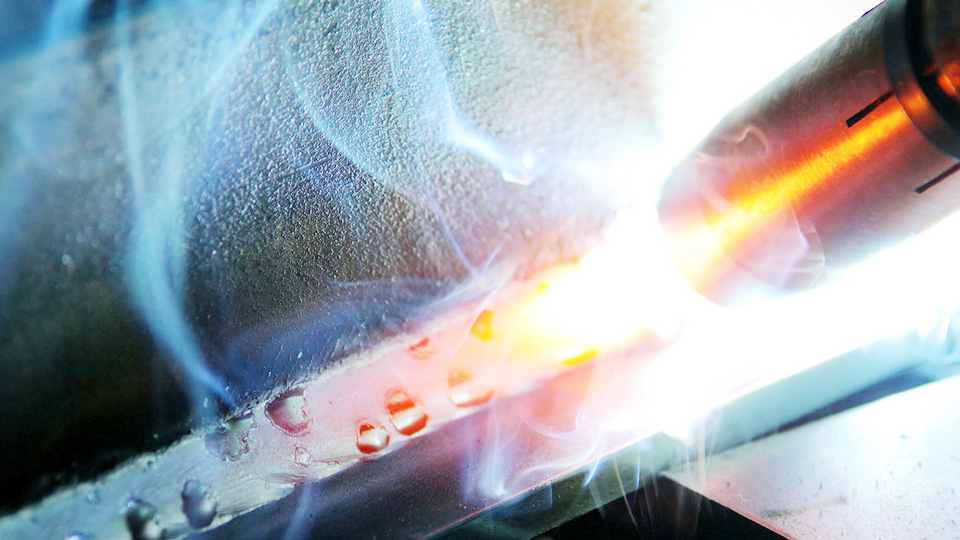

Image by teknikmesinmanufaktur

How Hot Pressure Welding Works

In hot pressure welding, heat is applied to the materials being welded to soften them, but not necessarily to melt them fully. This heating is typically achieved through external sources such as electric currents, gas flames, or induction.

Once the materials reach the appropriate temperature, pressure is applied, often through mechanical presses, to bring the materials into contact and form a solid bond.

The process can be divided into three stages:

Heating Stage

Heat is applied to the materials until they are malleable enough to deform under pressure. The temperature used varies depending on the materials, but it generally remains below their melting point.

Pressurizing Stage

Mechanical force is applied to the heated materials. This pressure causes the atoms of the two materials to come into contact, forming a solid-state bond.

Cooling Stage

Once the materials have been pressed together, the heat is removed, and the materials are allowed to cool. The joint solidifies and becomes as strong as or stronger than the parent materials.

Types of Hot Pressure Welding

There are several variations of hot pressure welding, each suited to specific applications and material types. These methods differ in how heat is applied and how the pressure is distributed. The most common types include:

Resistance Welding

In resistance hot pressure welding, an electric current is passed through the materials to generate heat at the contact point. The heat is produced by the resistance of the material to the current, and pressure is applied to forge the materials together. This method is commonly used in industries such as automotive manufacturing for joining thin sheets of metal.

Friction Welding

Friction welding is a form of hot pressure welding where heat is generated through mechanical friction. One of the materials is rotated or moved against the other at high speed, creating frictional heat at the interface.

Once the materials are sufficiently heated, they are pressed together, creating a strong weld. This method is often used for joining tubular components or parts that cannot be easily welded using other techniques.

Induction Welding

Induction welding uses electromagnetic induction to generate heat within the materials. This method is commonly employed in applications where precision is essential, as the heat can be localized to the weld zone. Pressure is applied after heating, making it suitable for joining pipes, tubes, and components with complex geometries.

Gas Pressure Welding

In gas pressure welding, a gas flame is used to heat the materials, typically using oxygen-acetylene torches. Once the materials reach the appropriate temperature, pressure is applied to create the bond. Gas pressure welding is particularly effective for large-scale applications like joining railroad tracks or structural beams.

Materials Suitable for Hot Pressure Welding

Hot pressure welding can be used with a wide range of materials, but it is particularly effective for metals and alloys. Some of the most commonly welded materials include:

- Steel: Steel is one of the most frequently welded materials in hot pressure welding. The process is ideal for joining different types of steel, including high-strength alloys.

- Aluminum: Hot pressure welding is used to join aluminum, especially in the aerospace and automotive industries where lightweight materials are essential.

- Copper: Due to its excellent conductivity, copper is often welded using hot pressure techniques in electrical engineering applications.

- Titanium: Known for its strength and resistance to corrosion, titanium is frequently welded using hot pressure methods in high-performance applications, such as in the aerospace sector.

Advantages of Hot Pressure Welding

Hot pressure welding offers several distinct advantages over other welding processes, making it a popular choice for various industrial applications. Some of these benefits include:

Strong, Durable Joints

The combination of heat and pressure in hot pressure welding creates joints that are often stronger than those produced by traditional fusion welding. Because the materials are not fully melted, the joint retains more of its original material properties, resulting in a more durable bond.

Ability to Join Dissimilar Metals

Hot pressure welding is particularly effective for joining dissimilar metals, which can be difficult to bond using other welding methods. The process allows for a gradual transition between different materials, minimizing the risk of cracking or distortion at the joint.

No Filler Material Required

Unlike some other welding techniques, hot pressure welding does not require the use of filler materials. This reduces the complexity of the welding process and ensures a cleaner, more uniform joint. It also eliminates the risk of contamination from filler materials, which can compromise the strength of the weld.

Minimized Thermal Distortion

Since the materials are not melted during the process, hot pressure welding reduces the risk of thermal distortion. This is particularly important in applications where maintaining the original shape and dimensions of the materials is crucial, such as in aerospace or precision engineering.

Versatility

Hot pressure welding is versatile and can be used with a wide range of metals and alloys. This flexibility makes it suitable for various industries, from automotive to electrical engineering, where different materials are commonly used.

Disadvantages of Hot Pressure Welding

While hot pressure welding has many advantages, it also has some limitations. These include:

Complex Equipment

The equipment required for hot pressure welding can be more complex and expensive than that used in traditional welding techniques. Specialized presses, heating systems, and monitoring equipment are often needed to ensure that the correct temperature and pressure are applied.

Limited to Certain Materials

While hot pressure welding is versatile, it is not suitable for all materials. Some materials, especially those with very high melting points or those that are highly brittle, may not be ideal for this welding process.

Slower Process

Compared to some other welding methods, hot pressure welding can be slower. The need to carefully control both heat and pressure means that the process may take longer, especially for larger components or complex welds.

Hot Pressure Welding vs Fusion Welding

Understanding the differences between hot pressure welding and fusion welding is crucial for selecting the right method for a specific application. Below is a comparison between the two welding techniques.

| Aspect | Hot Pressure Welding | Fusion Welding |

|---|---|---|

| Heat Application | Heat is applied to soften materials, not melt them. | Heat is applied to melt the materials at the joint. |

| Pressure Requirement | High pressure is required to bond materials. | Pressure is not typically required. |

| Filler Material | No filler material is needed. | Often requires a filler material. |

| Thermal Distortion | Minimal thermal distortion due to lack of melting. | Higher risk of distortion due to melting. |

| Suitable Materials | Ideal for joining dissimilar metals and alloys. | Can be used for a wide range of metals. |

| Strength of Weld | Typically produces stronger, more durable joints. | Strength depends on the materials and technique. |

| Applications | Aerospace, automotive, electrical components. | Construction, pipelines, general fabrication. |

Applications of Hot Pressure Welding

Hot pressure welding is used in a variety of industries due to its ability to create strong, reliable joints. Some of the most common applications include:

Aerospace

The aerospace industry often requires lightweight, high-strength materials that can withstand extreme stress and temperature variations. Hot pressure welding is ideal for joining aluminum and titanium components used in aircraft and spacecraft construction.

Automotive Manufacturing

In automotive manufacturing, hot pressure welding is used to join structural components, such as chassis and body panels. The process is also employed in the production of engine parts and exhaust systems, where strength and durability are critical.

Electrical Engineering

Hot pressure welding is widely used in electrical engineering to join conductive materials like copper and aluminum. This is particularly important in the production of wiring, cables, and electrical contacts, where efficient conductivity is essential.

Pipe and Tube Manufacturing

In industries where piping and tubing are used, hot pressure welding provides a reliable method for joining components with complex geometries. The process is commonly employed in oil and gas, chemical, and water treatment industries for creating durable, leak-proof joints.

Future Trends in Hot Pressure Welding

As technology advances, hot pressure welding continues to evolve. New materials, such as composites and advanced alloys, are being developed that can benefit from the precision and strength of hot pressure welding. Additionally, improvements in automation and robotics are making the process faster and more cost-effective, allowing for greater scalability in industries like automotive manufacturing.

Conclusion

Hot pressure welding is a versatile and reliable method for joining metals and alloys in a wide range of industries. By combining heat and pressure, this welding technique produces strong, durable joints without the need for filler materials or excessive heat. While it may require more complex equipment and careful control

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.