Solder flux plays a crucial role in the soldering process by ensuring clean and reliable connections. Its primary function is to remove oxides and contaminants from metal surfaces, allowing solder to adhere properly. Without flux, the solder would struggle to bond effectively, leading to weak joints and potential electronic failures. By promoting wetting, flux enables the solder to flow smoothly and evenly, creating strong connections that are essential for electronic devices to function optimally.

As electronics become more complex and miniaturized, the need for precise and reliable soldering has never been more critical. Solder flux acts as a catalyst, accelerating the soldering process and enhancing the overall quality of the joint. Whether you’re assembling a circuit board or repairing a delicate electronic component, the proper application of solder flux is key to achieving professional results.

Image by freeredar

Solder flux is available in various formulations to suit different soldering applications. From rosin flux to water-soluble flux, each type offers unique characteristics that cater to specific soldering requirements. Understanding the purpose of solder flux and choosing the right type for your project is essential for successful soldering outcomes.

Types of Solder Flux

When it comes to solder flux, one size does not fit all. Different types of flux are designed to address specific soldering challenges and materials. Rosin flux, derived from natural pine resin, is a common choice for general-purpose soldering due to its excellent solderability and reliability. It is available in both liquid and paste forms, offering versatility depending on the application.

For applications requiring cleaning after soldering, water-soluble flux provides an effective solution. This type of flux can be easily removed with water, making it ideal for situations where flux residue must be eliminated. No-clean flux, on the other hand, leaves behind a minimal residue that does not require cleaning, saving time and effort during the soldering process.

In addition to these traditional flux types, newer formulations such as low-temperature and no-clean lead-free flux have emerged to meet the demands of modern electronics manufacturing. These fluxes are designed to work with lead-free solder alloys while maintaining high reliability and performance standards.

How Solder Flux Works?

The chemistry behind solder flux is fascinating yet straightforward. When heated during the soldering process, flux undergoes a series of reactions that help prepare the metal surfaces for soldering. Flux works by reducing metal oxides, which can inhibit solder flow and weaken the bond. By dissolving these oxides and creating a clean surface, flux promotes wetting, allowing the solder to adhere to the metal more effectively.

In addition to removing oxides, solder flux also acts as a thermal conductor, helping to transfer heat evenly across the joint. This thermal conductivity ensures that the solder flows smoothly and solidifies without creating cold joints or voids. Furthermore, flux prevents oxidation by forming a protective barrier on the metal surfaces, preserving the integrity of the solder joint over time.

Understanding how solder flux works is essential for mastering the soldering process and achieving high-quality results. By harnessing the power of flux, soldering professionals can ensure reliable connections that meet the stringent requirements of modern electronics.

Image by gacha24,YT

Importance of Using Solder Flux in Soldering

The importance of using solder flux in soldering cannot be overstated. Flux is a critical component that directly impacts the quality and reliability of solder joints. Without flux, the soldering process becomes more challenging, leading to inferior connections that are prone to failure. By incorporating flux into your soldering workflow, you can enhance the wetting ability of the solder, improve thermal transfer, and prevent oxidation, ensuring robust and durable joints.

Solder flux plays a vital role in ensuring the longevity of electronic devices. By creating clean and solid solder connections, flux helps to mitigate issues such as cold joints, solder bridges, and poor wetting, which can compromise the functionality of electronic circuits. Whether you’re a hobbyist working on DIY projects or a professional soldering intricate components, the use of solder flux is essential for achieving consistent and reliable results.

In the ever-evolving landscape of electronics manufacturing and repair, the need for high-quality soldering has never been greater. Solder flux serves as a linchpin in the soldering process, enabling precise and efficient bonding that meets the stringent requirements of modern electronics. By understanding the importance of flux and its impact on soldering quality, you can elevate your soldering skills and produce flawless electronic assemblies.

Steps to Use Solder Flux Effectively

Using solder flux effectively is a skill that can significantly impact the quality of your soldering work. By following a few simple steps, you can ensure that the flux enhances the soldering process and facilitates strong, reliable connections. Here is a step-by-step guide on how to use solder flux effectively:

Prepare the surfaces

Before applying flux, ensure that the metal surfaces to be soldered are clean and free of contaminants. Use a suitable cleaning agent or abrasive tool to remove any oxidation or debris that may hinder solder adhesion.

Apply the flux

Using a brush, syringe, or flux pen, apply a thin, even layer of flux to the metal surfaces. Be careful not to apply too much flux, as excess flux can lead to solder bridges or poor wetting.

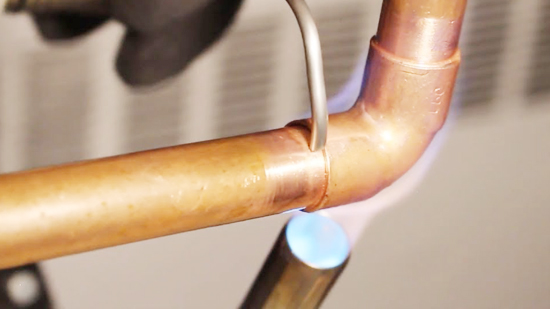

Heat the joint

Once the flux is applied, heat the metal surfaces using a soldering iron or reflow oven. The flux will activate and begin to remove oxides, allowing the solder to flow smoothly and adhere to the metal.

Solder the joint

With the flux activated, apply the solder to the heated surfaces. The flux will help the solder flow and bond to the metal, creating a strong and reliable connection.

Clean the residue

After soldering, remove any flux residue using a suitable cleaning agent or flux remover. Proper cleaning ensures that the solder joint is free from contaminants and oxidation, preserving its integrity over time.

By following these steps and practicing proper soldering techniques, you can harness the full potential of solder flux and achieve professional results in your soldering projects. Remember, the key to successful soldering lies in understanding the role of flux and using it effectively to create durable and reliable connections.

Image by shutterstock

Precautions While Using Solder Flux

While solder flux is a valuable ally in the soldering process, it is essential to take precautions to ensure safe and effective use. Here are some precautions to keep in mind when working with solder flux:

Ventilation

Solder flux can release fumes when heated, which may be harmful if inhaled. Always work in a well-ventilated area or use a fume extractor to remove potentially hazardous fumes from the soldering workspace.

Skin protection

Some types of flux may cause skin irritation or allergic reactions upon contact. Wear protective gloves when handling flux to prevent skin exposure and potential health risks.

Eye protection

In the event of flux splashes or fumes, wear safety goggles to protect your eyes from irritation or injury. Flux can be corrosive and should be kept away from sensitive areas such as the eyes.

Storage

Properly store flux containers in a cool, dry place away from direct sunlight and heat sources. Ensure that the containers are tightly sealed to prevent contamination or evaporation of the flux.

Cleanup

After soldering, clean up any flux residue using a dedicated flux remover or cleaning agent. Proper cleanup not only ensures the longevity of the solder joint but also maintains a tidy work environment.

By observing these precautions and practicing safe soldering habits, you can maximize the benefits of solder flux while safeguarding your health and well-being. Remember, soldering is a rewarding skill that requires attention to detail and a commitment to safety at all times.

Common Mistakes to Avoid When Using Solder Flux

Despite its importance in the soldering process, solder flux can be misused, leading to subpar results and potential damage to electronic components. To help you avoid common pitfalls, here are some mistakes to steer clear of when using solder flux:

Applying too much flux

Excess flux can create solder bridges, poor wetting, and other soldering defects. Use only the necessary amount of flux to achieve optimal results without causing soldering issues.

Using the wrong type of flux

Different soldering applications require specific types of flux. Using the wrong flux can result in poor solder adhesion, weak joints, and overall soldering failures. Choose the appropriate flux for your soldering project to ensure success.

Neglecting cleanup

Failure to clean flux residue after soldering can lead to corrosion, electrical shorts, and other reliability issues. Always remove flux residue using a suitable cleaning agent to maintain the integrity of the solder joint.

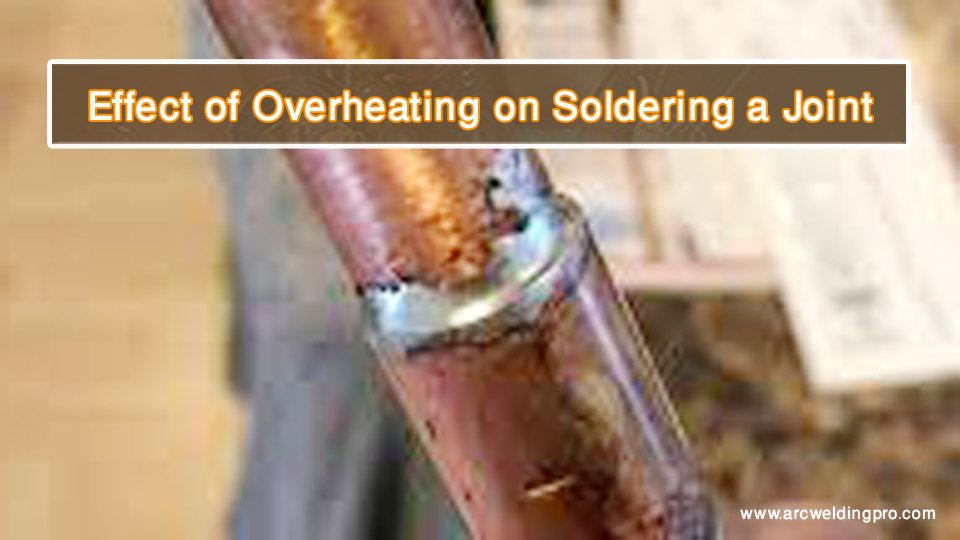

Overheating the flux

Excessive heat can degrade the effectiveness of flux and lead to soldering problems. Follow the manufacturer’s recommendations for temperature settings and soldering durations to prevent flux degradation.

Skipping flux application

Some solder alloys may claim to be self-fluxing, but using additional flux can improve the quality of the solder joint. Don’t overlook the benefits of flux in enhancing solder wetting and reliability.

By being mindful of these common mistakes and adopting best practices in solder flux application, you can elevate your soldering skills and achieve consistent, high-quality results in your electronic projects. Remember, attention to detail and precision are key to mastering the art of soldering with flux.

Image by homedepot

Troubleshooting Tips for Soldering with Flux

Even with careful preparation and proper flux application, soldering issues can still arise. Knowing how to troubleshoot common soldering problems can help you overcome challenges and achieve successful solder joints. Here are some troubleshooting tips for soldering with flux:

Incomplete wetting

If the solder does not flow smoothly or evenly across the joint, inadequate wetting may be the issue. Reapply flux to the joint and ensure proper heating to promote better wetting and solder adhesion.

Excessive solder balling

When solder forms into balls rather than spreading evenly, flux can help improve solder flow and wetting. Apply flux to the joint and adjust the soldering temperature to achieve the desired soldering outcome.

Solder bridges

Flux can help prevent solder bridges by promoting proper wetting and preventing solder from spreading where it shouldn’t. Use flux to control solder flow and ensure clean, distinct solder joints.

Cold joints

Inadequate heating or insufficient flux coverage can result in cold joints, which are weak and unreliable. Reheat the joint while applying flux to achieve proper solder wetting and bonding.

Oxidation

If oxidation occurs during soldering, flux can help remove oxides and create a clean surface for solder adhesion. Apply flux to the joint and reheat to eliminate oxidation and ensure a reliable solder connection.

By applying these troubleshooting tips and leveraging the benefits of solder flux, you can address common soldering challenges with confidence and precision. Remember, practice makes perfect, and mastering the art of soldering with flux requires patience, persistence, and a commitment to continuous improvement.

Conclusion

Solder flux is a fundamental component in the world of soldering, essential for achieving clean, reliable, and durable solder joints. By understanding the purpose of solder flux, exploring the different types available, and learning how to use flux effectively, you can elevate your soldering skills and produce professional-grade electronic assemblies. Whether you’re a novice enthusiast or a seasoned soldering professional, the role of flux in soldering cannot be overstated.

As you embark on your soldering projects, remember to follow best practices in flux application, observe safety precautions, and troubleshoot common soldering issues with confidence. Soldering with flux is both an art and a science, requiring precision, patience, and a keen eye for detail. With practice and dedication, you can harness the power of solder flux to create flawless solder connections that stand the test of time.

In the dynamic world of electronics manufacturing and repair, solder flux remains a steadfast ally, enabling the seamless integration of components and the reliable operation of electronic devices. By embracing the principles of soldering with flux and staying abreast of advancements in soldering technology, you can position yourself as a proficient soldering professional capable of tackling any soldering challenge with finesse.

Soldering is not just a technical skill but a craft that demands creativity, ingenuity, and a passion for precision. With solder flux as your trusted companion, you can embark on soldering adventures with confidence, knowing that your solder joints are built to last and perform flawlessly. So, equip yourself with the knowledge, tools, and enthusiasm to excel in the art of soldering with flux, and let your soldering projects shine bright in the world of electronics.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.