Ultrasonic welding is a highly efficient and precise technique used to join materials, particularly plastics and metals, through high-frequency acoustic vibrations. This process is widely used across various industries due to its speed, cleanliness, and ability to produce strong, consistent bonds without the need for additional materials like adhesives or solder.

Understanding the ultrasonic welding process can provide insights into its applications, benefits, and how it compares to other welding methods.

Image by

What is Ultrasonic Welding

Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic vibrations to join materials, typically plastics and some metals. Unlike traditional welding methods that rely on heat from an external source, ultrasonic welding generates heat through mechanical vibrations applied to the workpieces under pressure. This heat causes the materials to soften and fuse at the molecular level, forming a strong bond.

Features of Ultrasonic Welding

- No Need for Additional Materials: Ultrasonic welding does not require adhesives, solder, or fasteners, reducing material costs and eliminating the need for additional processing steps.

- Environmentally Friendly: The process does not produce harmful fumes or waste, making it suitable for cleanroom environments.

- Speed and Efficiency: Ultrasonic welding is a rapid process, often completing in a few seconds, which makes it ideal for high-volume production.

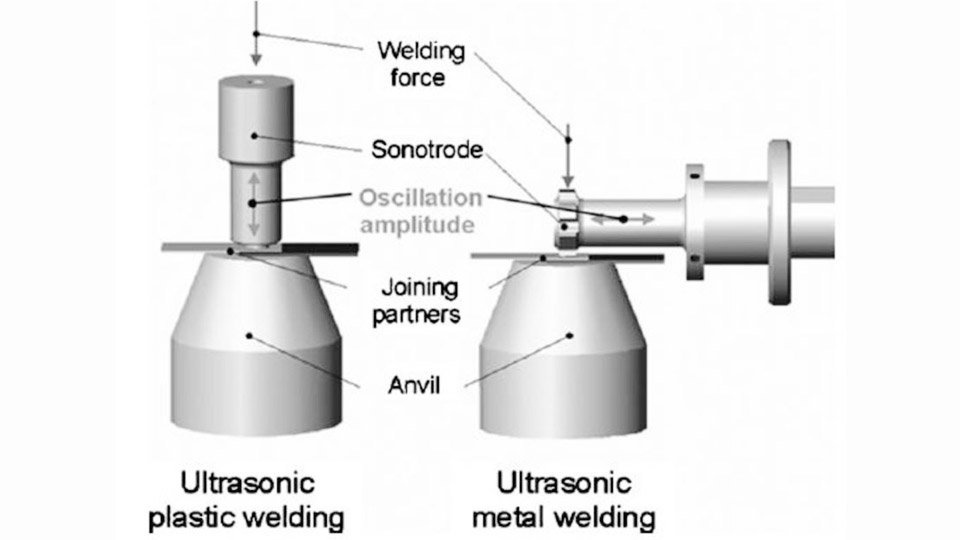

Components of the Ultrasonic Welding System

The ultrasonic welding system consists of several key components that work together to generate and apply ultrasonic vibrations to the materials being joined.

Power Supply

The power supply converts standard electrical energy from a power outlet into high-frequency electrical energy. This high-frequency energy is crucial for generating the ultrasonic vibrations needed for the welding process.

Transducer

The transducer is a critical component that converts the high-frequency electrical energy from the power supply into mechanical vibrations. This conversion is achieved using piezoelectric crystals, which change shape when exposed to an electric field, thereby generating mechanical motion.

Booster

The booster amplifies the mechanical vibrations produced by the transducer. It also serves as a mounting point for the horn, enhancing the overall efficiency and control of the vibrations applied to the workpieces.

Horn (Sonotrode)

The horn, also known as the sonotrode, is the tool that directly applies the ultrasonic vibrations to the materials being welded. It is specifically designed to match the shape and requirements of the welding process, ensuring effective transmission of energy to the joint area.

Fixture (Anvil)

The fixture, or anvil, holds the workpieces in place during the welding process. It ensures proper alignment and consistent pressure, which are critical for achieving high-quality welds.

Ultrasonic Welding Process

The ultrasonic welding process involves a series of steps that ensure a reliable and strong bond between the materials being joined. Each step is carefully controlled to optimize the welding outcome.

Preparation

Before welding, the materials must be properly prepared. This includes cleaning the surfaces to remove any contaminants that could interfere with the welding process. The parts are then positioned in the fixture to ensure correct alignment.

Welding Cycle

- Clamping: The materials are clamped between the horn and the fixture, securing them in place.

- Application of Ultrasonic Vibrations: The power supply sends high-frequency electrical energy to the transducer, which converts it into mechanical vibrations. These vibrations are amplified by the booster and transmitted through the horn to the workpieces.

- Heat Generation: The vibrations generate frictional heat at the interface of the materials, causing them to soften and fuse.

- Cooling and Solidification: After the vibrations stop, the materials cool under pressure, solidifying the bond.

Post-Welding Inspection

Following the welding cycle, the joint is inspected to ensure it meets the required standards for strength and quality. This inspection can include visual checks, tensile testing, and non-destructive evaluation methods.

Applications of Ultrasonic Welding

Ultrasonic welding is used in a variety of industries due to its versatility and efficiency. Below are some common applications:

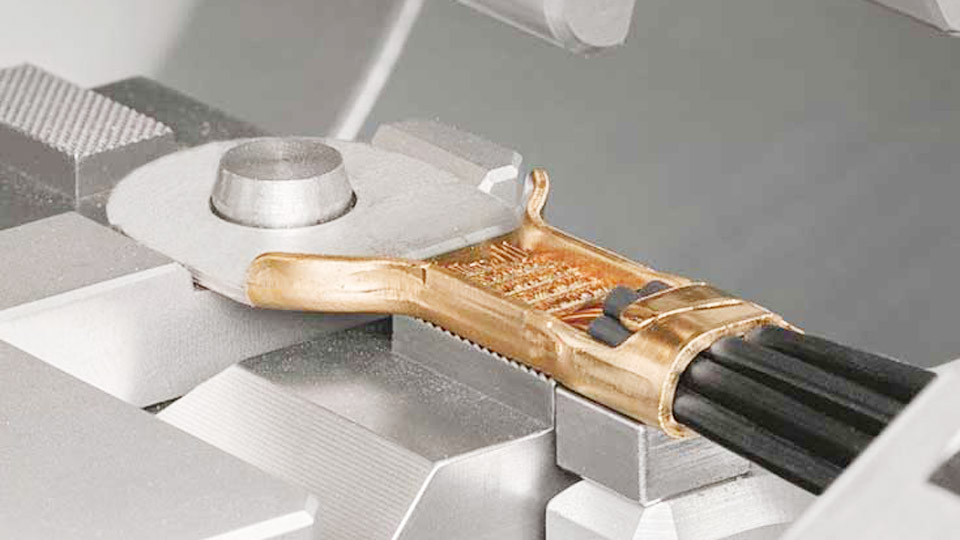

Automotive Industry

Ultrasonic welding is used to join plastic components in vehicles, such as dashboards, door panels, and airbag covers. It is also employed in assembling electrical components like wiring harnesses and sensors.

Electronics

In the electronics industry, ultrasonic welding is used to weld delicate components, such as circuit boards, connectors, and battery packs, without damaging sensitive parts.

Medical Devices

Ultrasonic welding is ideal for joining plastic parts in medical devices, such as IV tubes, filters, and surgical instruments, where sterility and precision are critical.

Packaging

The packaging industry uses ultrasonic welding to seal packages, such as blister packs and plastic containers, without using heat that could damage the contents.

Advantages of Ultrasonic Welding

Ultrasonic welding offers numerous advantages, making it a preferred choice for many manufacturing applications.

- High Speed: The process is extremely fast, often completing in a few seconds, which increases production efficiency.

- Cost-Effective: By eliminating the need for additional materials like adhesives or fasteners, ultrasonic welding reduces overall production costs.

- Strong and Reliable Bonds: Ultrasonic welding creates strong, durable bonds that can withstand mechanical stresses.

- Minimal Environmental Impact: The process does not produce harmful emissions, making it environmentally friendly.

- Flexibility: It can be used to join a wide range of materials, including dissimilar plastics and some metals.

Limitations of Ultrasonic Welding

While ultrasonic welding is highly beneficial, it also has some limitations that need to be considered.

- Material Restrictions: The process is most effective with thermoplastics and certain metals. Materials that do not conduct ultrasonic energy well may not be suitable.

- Thickness Limitation: Ultrasonic welding is generally limited to thinner materials, as thicker parts can absorb the vibrations, reducing the effectiveness of the weld.

- Initial Equipment Cost: The setup cost for ultrasonic welding equipment can be high, which may be a barrier for small-scale operations.

- Precision Requirement: The process requires precise control of welding parameters and alignment of parts, which can complicate the setup for complex geometries.

Ultrasonic Welding with Other Welding Methods

To understand the unique advantages of ultrasonic welding, it is useful to compare it with other common welding methods, such as heat welding and adhesive bonding.

| Feature | Ultrasonic Welding | Heat Welding | Adhesive Bonding |

|---|---|---|---|

| Heat Source | Frictional heat from vibrations | External heat source | Chemical reaction |

| Materials Joined | Thermoplastics, some metals | Metals, plastics | Plastics, composites |

| Speed | Fast (seconds) | Slow to moderate | Moderate |

| Need for Consumables | No | Yes (filler materials) | Yes (adhesives) |

| Energy Efficiency | High | Moderate | Low to moderate |

| Environmental Impact | Low (no emissions) | High (fumes, emissions) | Low to moderate |

| Joint Strength | High | High | Moderate |

| Equipment Cost | High | Moderate to high | Low to moderate |

| Applications | Automotive, electronics, medical | Construction, automotive | Packaging, general use |

Factors Affecting Ultrasonic Welding Quality

Several factors can influence the quality of ultrasonic welds, making it essential to optimize these variables for the best results.

Material Properties

- Compatibility: The materials should have similar melting points and compatible molecular structures to achieve a strong weld.

- Surface Condition: Clean, smooth surfaces are essential for good welding quality. Contaminants can lead to weak bonds.

Welding Parameters

- Amplitude: The amplitude of the vibrations must be correctly set to ensure sufficient heat generation without damaging the parts.

- Pressure: Proper clamping pressure ensures good contact between the parts, aiding in efficient energy transfer.

- Weld Time: The duration of the welding cycle must be carefully controlled to avoid under-welding or over-welding.

Design of the Horn and Fixture

- Horn Design: The horn should be designed to match the shape of the parts and ensure uniform energy distribution across the joint.

- Fixture Design: A well-designed fixture is crucial for holding the parts securely and maintaining consistent pressure during welding.

Future Trends in Ultrasonic Welding

Ultrasonic welding technology continues to evolve, with new developments enhancing its capabilities and expanding its applications.

- Automation and Robotics: Integration with automated systems and robots is increasing, allowing for fully automated production lines that enhance speed and consistency.

- Advanced Materials: New horn designs and materials are being developed to expand the range of compatible materials, including advanced composites.

- Real-Time Monitoring: Advanced sensors and monitoring systems are being incorporated to provide real-time feedback on the welding process, improving quality control and reducing defects.

Conclusion

Ultrasonic welding is a powerful and versatile joining technique that offers significant advantages over traditional welding methods. Its ability to create strong, reliable bonds without additional materials, combined with its speed, cleanliness, and energy efficiency, makes it a preferred choice in many industries.

Despite some limitations, the ongoing advancements in ultrasonic welding technology are likely to further enhance its performance and broaden its applications, solidifying its role as a key tool in modern manufacturing. Whether used in automotive, electronics, medical devices, or packaging, ultrasonic welding continues to drive innovation and efficiency in production processes.

I’m Darrell Julian, the founder, lead writer, and hands-on welding enthusiast behind ArcWeldingPro.com. With more than 15 years of real-world welding experience, I created this platform to share what I’ve learned in the field, in the shop, and in the heat of the arc.